The Importance of Wire Harnesses in Automotive Applications

Wire harnesses play a fundamental role in the modern automotive industry. They are the critical components that connect all the electrical systems within a vehicle, facilitating the smooth and reliable operation of power, data transmission, and control signals between various parts. With the increasing complexity of automotive electronics, the demand for high-quality wire harnesses has grown significantly.

As vehicles become more sophisticated, integrating numerous electrical and electronic components, wire harnesses have evolved to meet new demands. These components ensure that everything from the engine to the infotainment system operates seamlessly and efficiently. Without a properly functioning wire harness, many of the features we take for granted in today’s vehicles, including safety systems, navigation, and entertainment, would not be possible.

In the case of Cixi Tengyu Electric Appliance Co., Ltd., our expertise in manufacturing wire harnesses is central to providing top-quality products that meet the specific needs of our automotive clients. By integrating advanced manufacturing techniques and high-quality materials, we produce wire harnesses that offer optimal performance, durability, and flexibility in all types of automotive applications.

What is a Wire Harness?

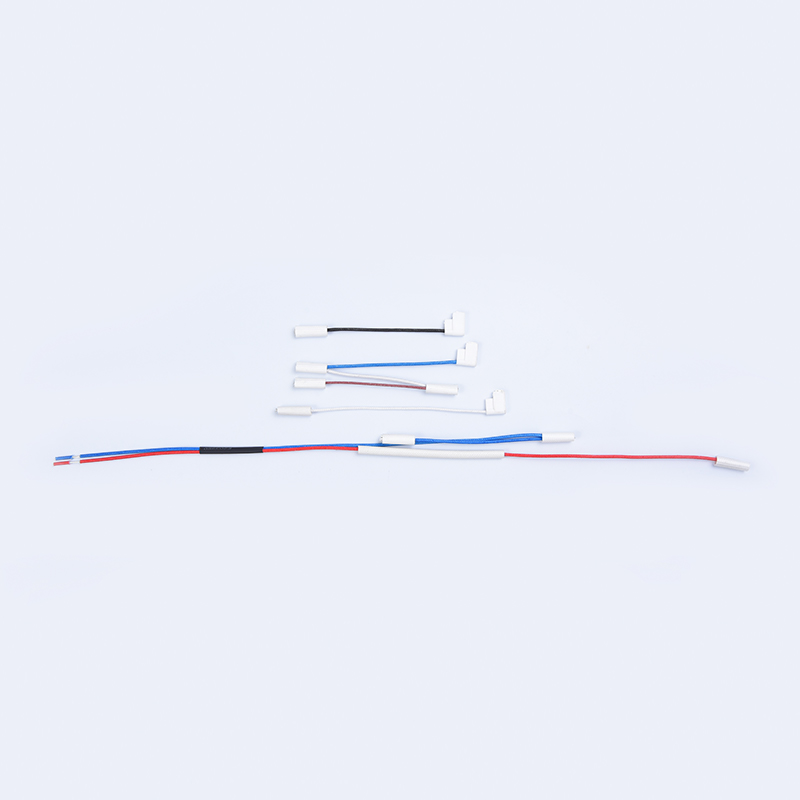

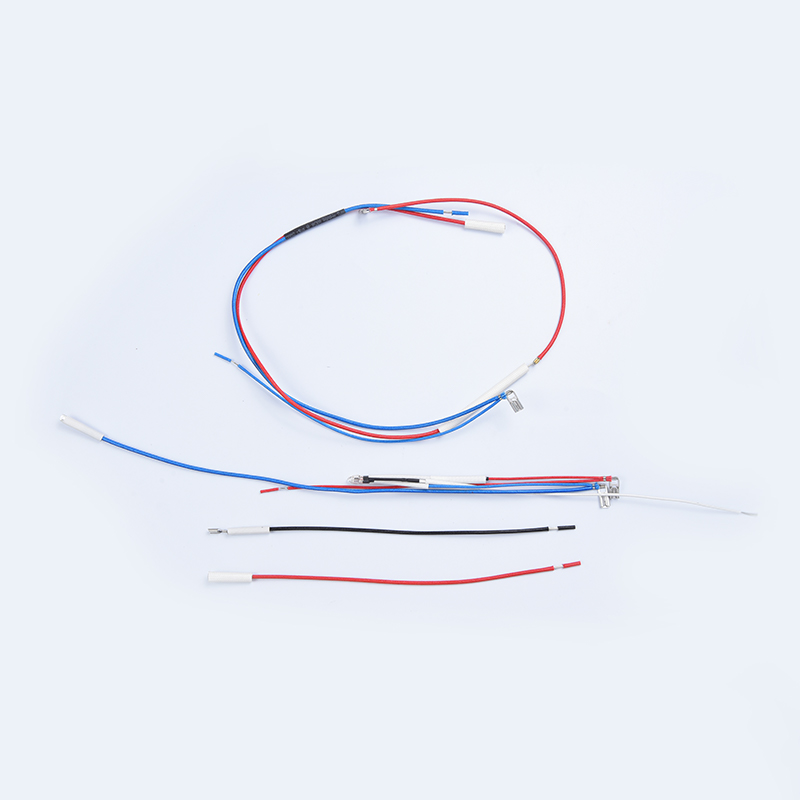

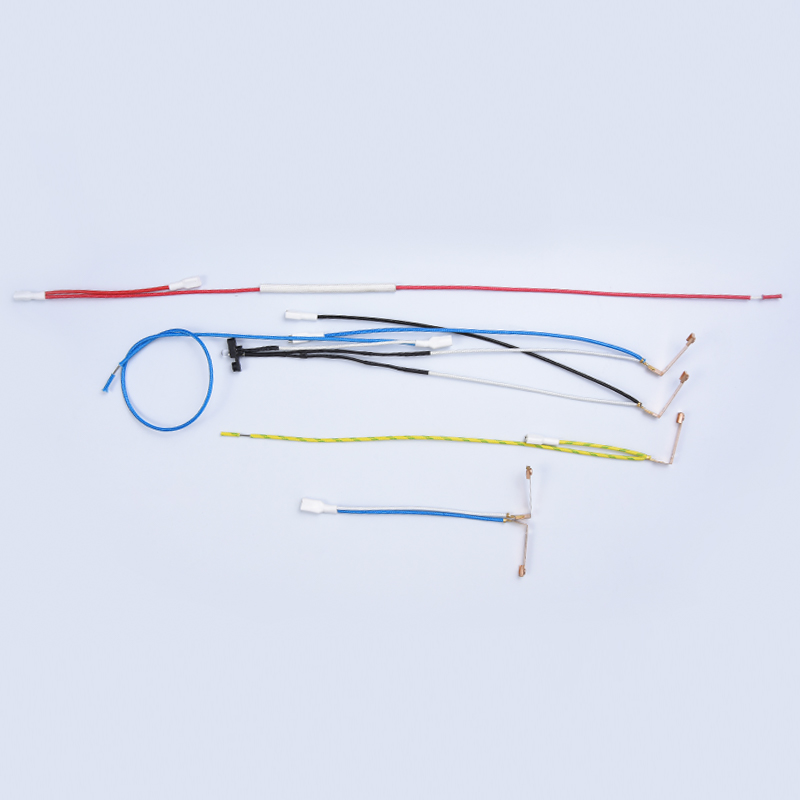

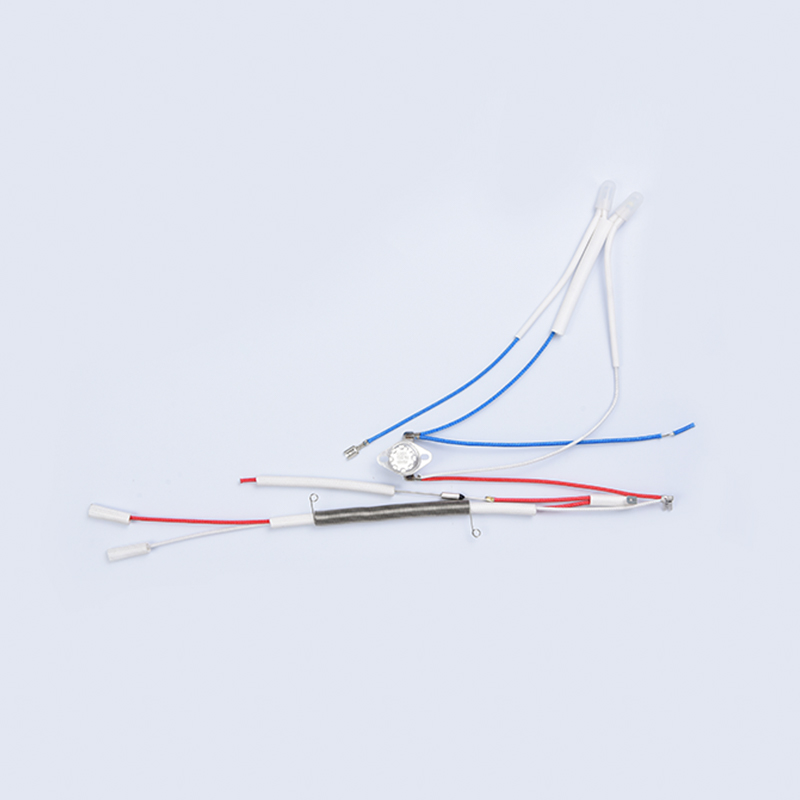

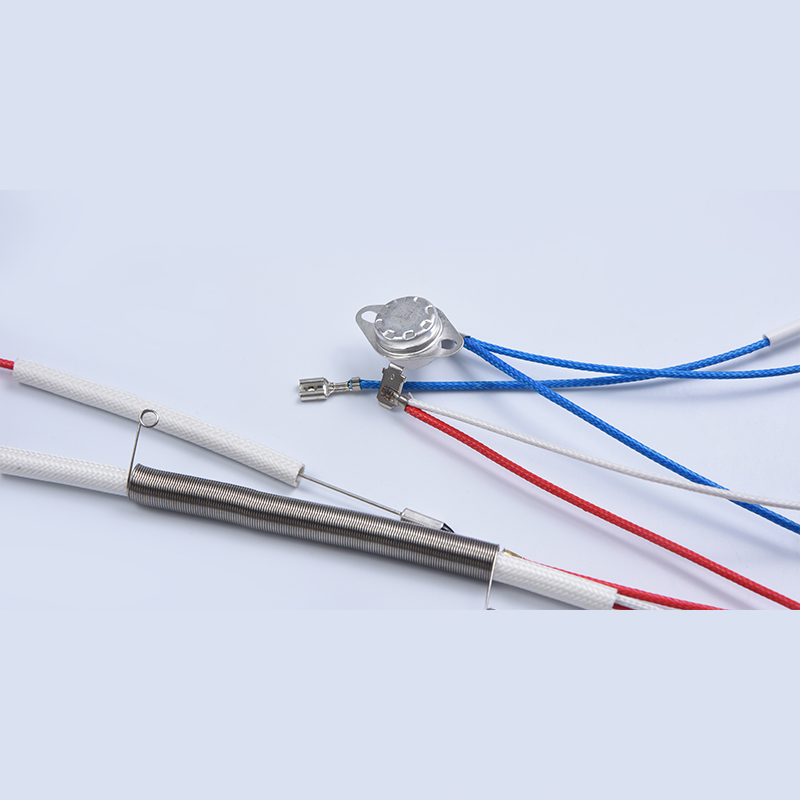

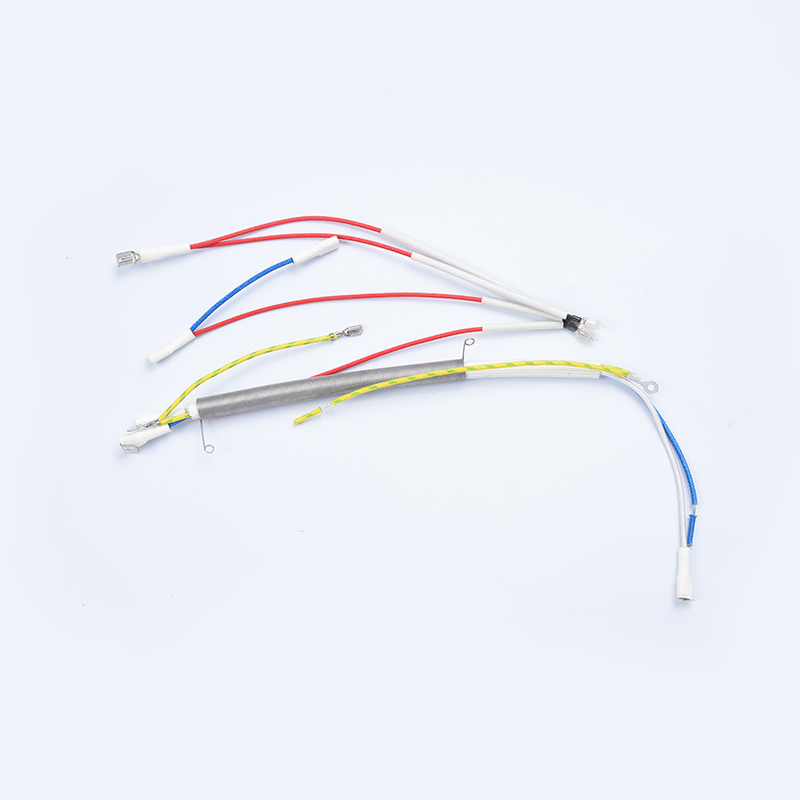

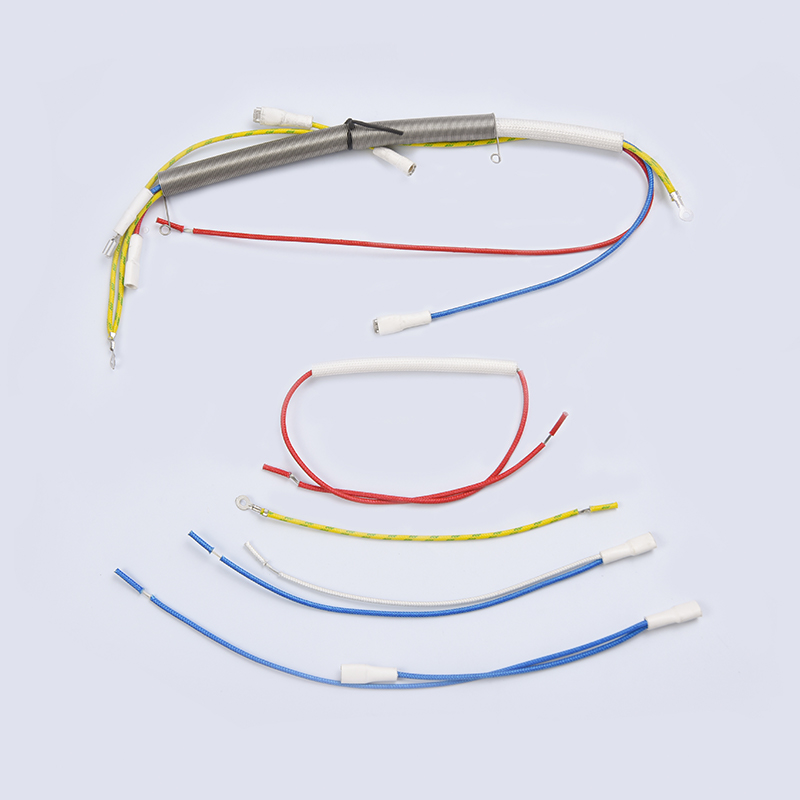

A wire harness, often referred to as a cable assembly or wiring loom, is an organized collection of wires, connectors, and terminals that facilitate the transmission of electrical power and signals between various components in a vehicle. This system ensures that power and data flow efficiently between different parts of the vehicle, such as the engine, battery, safety features, and electronic systems.

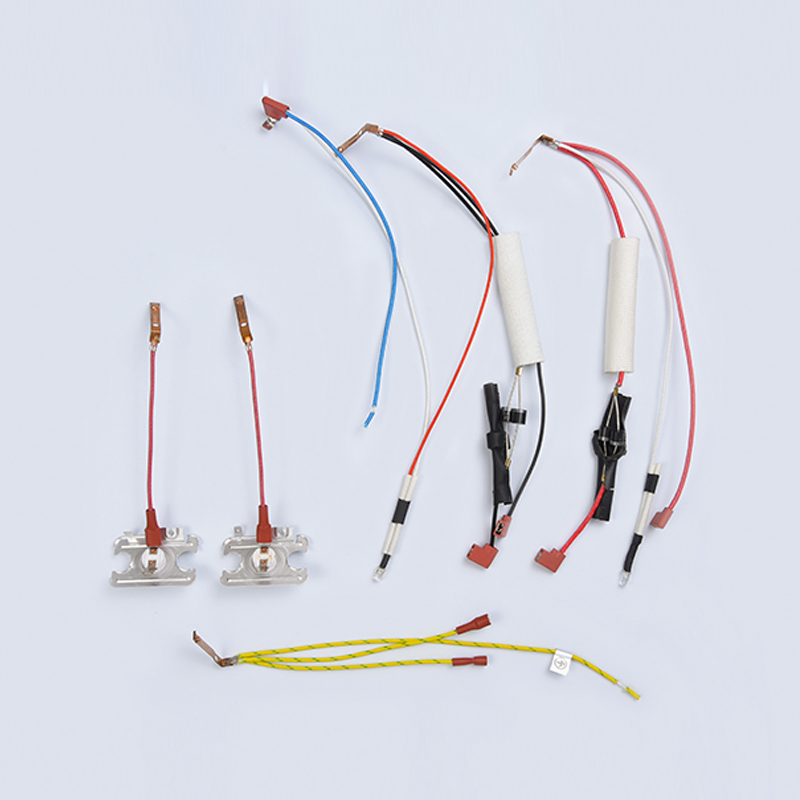

The wire harness typically includes multiple elements, including:

-

Wires: Made from conductive materials such as copper or aluminum, these are responsible for carrying electrical current to various components of the vehicle.

-

Connectors: These are used to join the wires to different electrical devices or components. They ensure a secure connection and reliable transmission of power or signals.

-

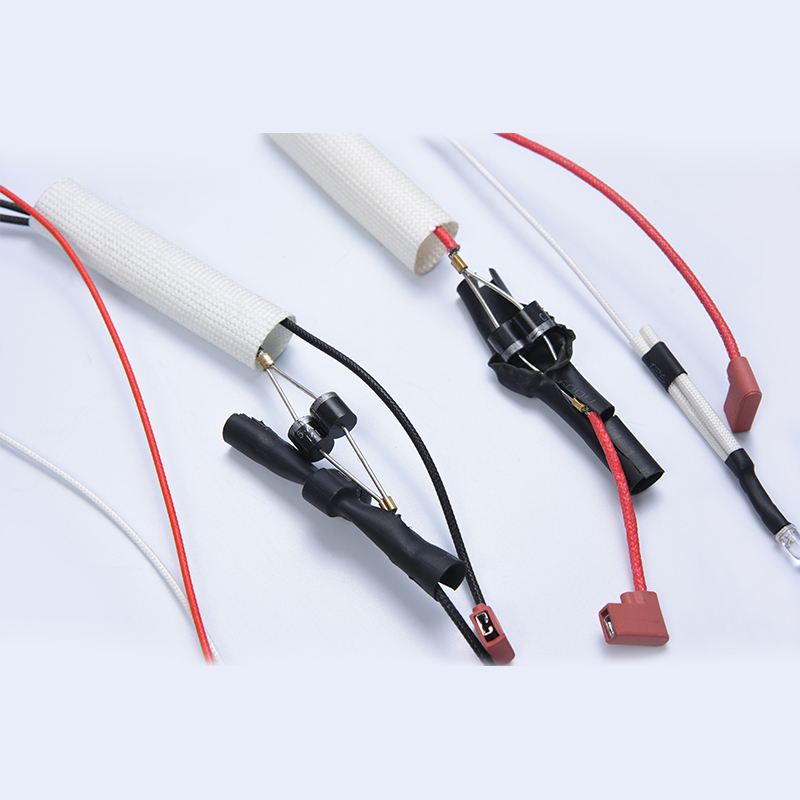

Insulation: The wires are typically covered in an insulating layer to prevent electrical shorts, exposure to environmental elements, or damage due to friction or heat.

-

Fasteners and Protective Sleeving: Clips, ties, and tubing are used to secure the harness to the vehicle’s frame and to protect it from physical wear and environmental damage.

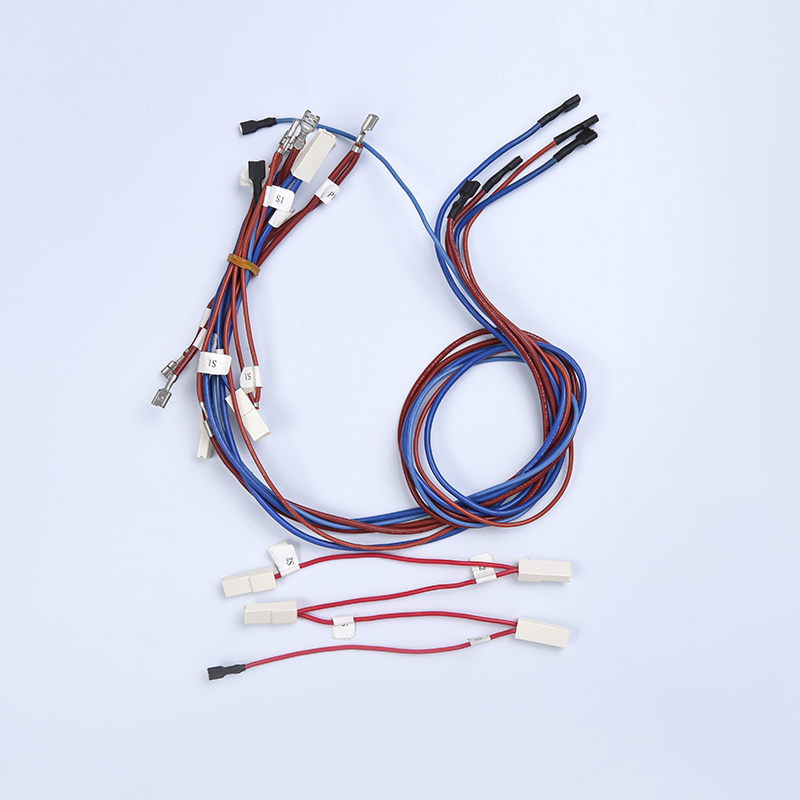

In modern automobiles, wire harnesses are complex and highly customized. They often include hundreds, or even thousands, of individual wires bundled together, each serving a specific purpose. They can be designed for a variety of functions, ranging from simple power distribution to advanced signal transmission for features like airbags, ABS brakes, and power-assisted steering.

At Cixi Tengyu Electric Appliance Co., Ltd., we specialize in the design and manufacture of high-performance wire harnesses. Our solutions are tailored to meet the needs of both conventional and emerging automotive technologies. We work closely with automotive manufacturers to ensure our wire harnesses meet the specific requirements for each vehicle model, delivering optimal performance and reliability in all driving conditions.

The Role of Auto Parts Wiring Harnesses in Vehicles

Auto parts wiring harnesses are the backbone of modern vehicle electrical systems. These assemblies not only connect the power source (typically the vehicle's battery or alternator) to the various electrical components but also ensure that the vehicle's sensors, safety systems, and entertainment features operate smoothly. The role of these harnesses is critical in ensuring that electrical power and data are transmitted reliably across the vehicle, especially in the context of safety and performance.

Here are some key functions that auto parts wiring harnesses serve in vehicles:

-

Power Distribution: One of the most essential roles of the wire harness is distributing electrical power from the vehicle’s main battery to various electrical components. This includes everything from lights and indicators to climate control systems and the engine’s control unit (ECU). A properly designed wire harness ensures that power is efficiently delivered to each part without interference or power loss.

-

Signal Transmission: In addition to power distribution, wire harnesses also transmit data signals for a range of systems. These may include the vehicle's infotainment system, climate controls, and advanced driver assistance systems (ADAS) such as parking sensors, cameras, and lane-keeping assistance. The integrity of the wiring is essential to ensure that these systems function correctly.

-

Safety and Reliability: One of the most critical areas where wire harnesses come into play is in ensuring vehicle safety. Systems like airbags, anti-lock braking (ABS), and stability control depend on the continuous flow of power and data via wire harnesses. Any failure in these systems could lead to severe safety risks. Therefore, it is vital that wire harnesses are manufactured with the highest standards of quality and reliability.

-

Simplification of Assembly: Auto parts wiring harnesses simplify the assembly process for vehicle manufacturers. Instead of having to connect individual wires to each component, a pre-assembled wiring harness can be installed, saving time and reducing the complexity of manufacturing. This also helps reduce labor costs and improves production efficiency.

At Cixi Tengyu Electric Appliance Co., Ltd., we are committed to delivering high-quality wiring harnesses that meet the growing demands of the automotive industry. Our team works diligently to ensure that each harness is designed to withstand the harsh conditions of automotive environments, from extreme temperatures to vibrations and exposure to moisture.

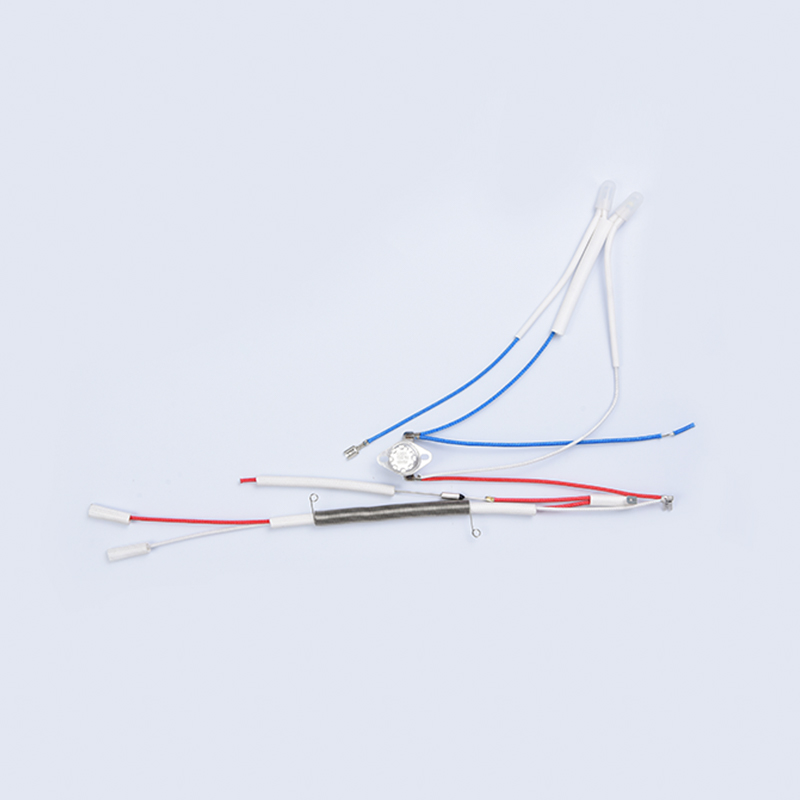

As the automotive industry increasingly focuses on electric vehicles (EVs), wire harnesses play an even more significant role. EVs require specialized harnesses to manage the high voltage systems and multiple sensors that ensure safe and efficient operation. Cixi Tengyu Electric Appliance Co., Ltd. is at the forefront of developing wiring solutions tailored to the unique needs of electric and hybrid vehicles.

Trends and Innovations in Automotive Wire Harness Technology

The automotive industry is undergoing rapid transformations, and these changes are influencing the development of wire harness technology. New vehicle technologies, stricter environmental standards, and increasing consumer demand for advanced features all require innovation in wire harness design. Companies like Cixi Tengyu Electric Appliance Co., Ltd. are responding to these needs by creating more efficient, reliable, and advanced wire harness solutions.

Some of the major trends and innovations in wire harness technology include:

-

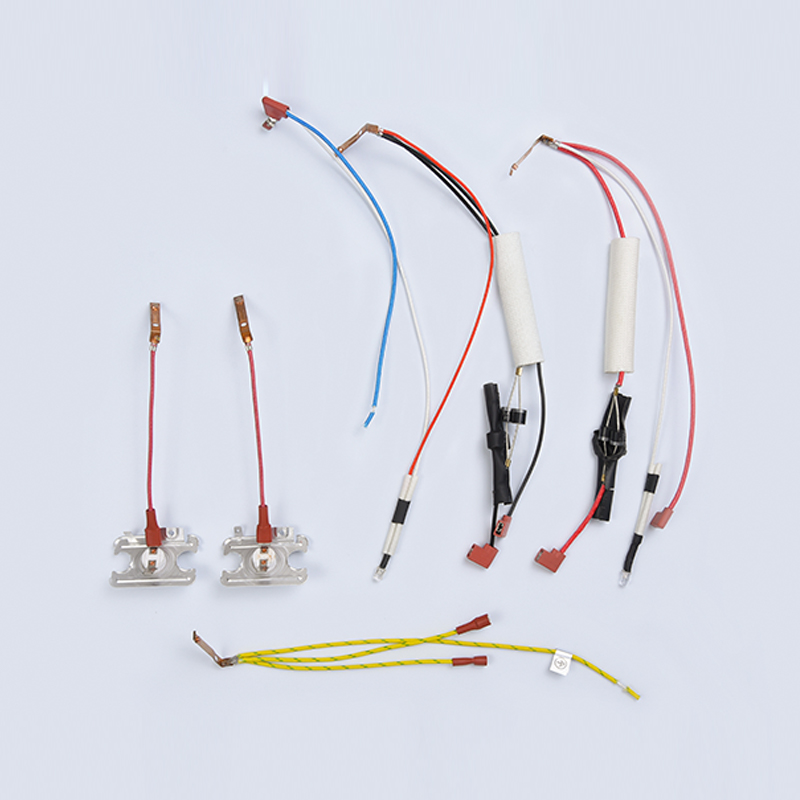

Lightweight Materials: With the automotive industry’s push for better fuel efficiency and reduced environmental impact, manufacturers are focusing on reducing vehicle weight. Wire harnesses are no exception to this trend. Lightweight materials, such as aluminum wires or composite fibers, are being used to reduce the overall weight of the harnesses without compromising performance or safety. These materials offer additional benefits in terms of flexibility and ease of installation.

-

Electrification and Hybrid Vehicles: As electric and hybrid vehicles become more prevalent, the need for specialized wire harnesses has increased. These vehicles require higher-voltage wiring systems to manage battery power and ensure efficient operation. Electric vehicles are equipped with advanced systems like regenerative braking, advanced thermal management, and high-tech communication systems that demand more robust and durable wire harness solutions. Cixi Tengyu Electric Appliance Co., Ltd. is actively involved in developing wiring solutions for EVs, providing harnesses that can handle these unique requirements.

-

Enhanced Durability and Protection: Automotive wire harnesses must withstand a variety of challenging environmental factors, including high temperatures, humidity, vibration, and exposure to oils and chemicals. To meet these challenges, manufacturers are using more advanced materials and protective coatings to ensure that wire harnesses remain durable throughout the vehicle's lifespan. Innovations in heat-resistant insulations, abrasion-resistant coatings, and moisture-proof designs are all contributing to the increased longevity and reliability of wire harnesses.

-

Integration with Smart Technologies: With the increasing integration of smart technologies in vehicles, wire harnesses are also evolving to handle more data-heavy tasks. Advanced driver assistance systems (ADAS), infotainment systems, and connected car technologies require high-speed data transmission capabilities. Wire harnesses are being designed with these requirements in mind, supporting faster data transfer and more complex wiring configurations.

Cixi Tengyu Electric Appliance Co., Ltd. continues to invest in research and development to stay at the forefront of these technological advancements. Our company is dedicated to providing cutting-edge wire harness solutions that meet the needs of the evolving automotive landscape, from electric vehicles to autonomous driving technologies.

中文简体

中文简体