Steak machines, or automatic steak grilling and cooking machines, have revolutionized the food industry by ensuring consistency, speed, and quality in the preparation of steaks and other meats. However, these complex machines require sophisticated electrical systems to function efficiently. The wiring harnesses used in these machines are critical to their operation, ensuring safe and reliable electrical connections throughout the system. Cixi Tengyu Electric Appliance Co., Ltd. stands at the forefront of manufacturing wiring harnesses for steak machines, offering solutions that meet the highest standards of functionality and durability.

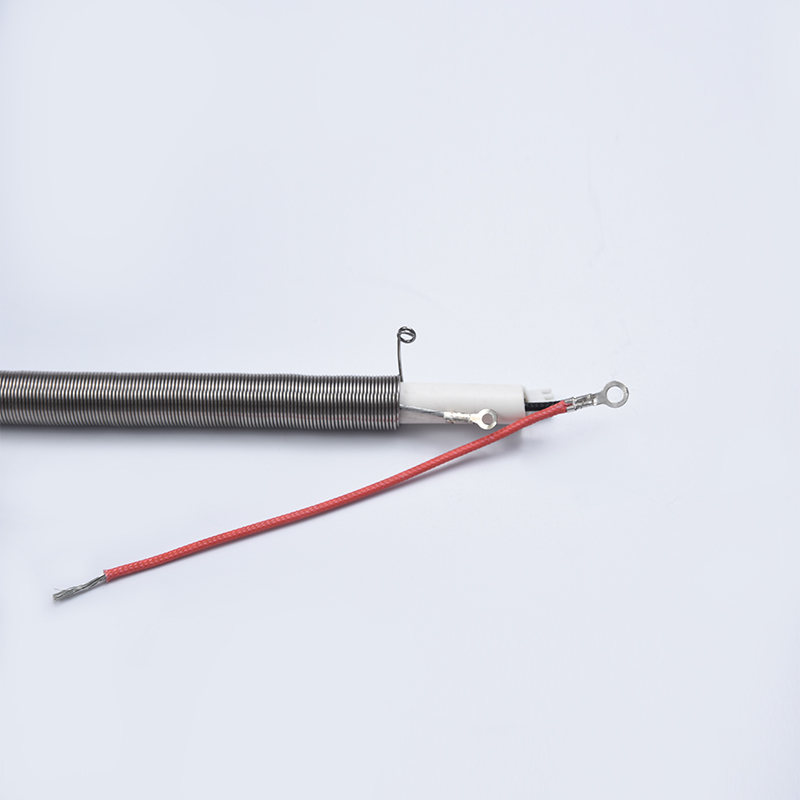

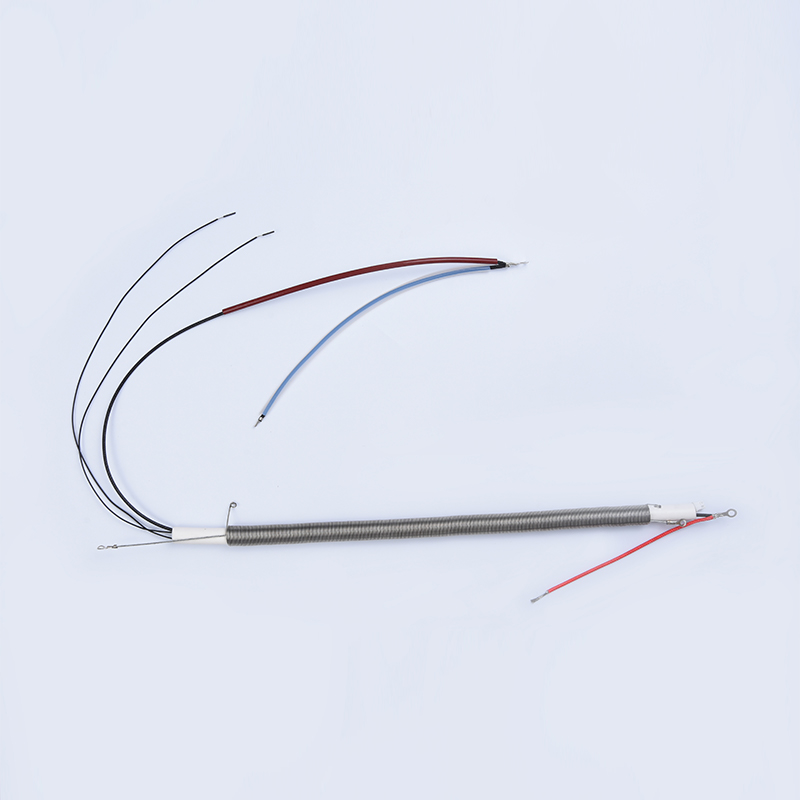

The wiring harnesses in steak machines connect various components, including sensors, motors, control panels, and heating elements. These connections ensure smooth communication between all parts of the machine, allowing it to perform tasks like temperature regulation, timer control, and automatic cooking. Without reliable wiring harnesses, steak machines would face frequent breakdowns, inconsistent results, and safety hazards. Cixi Tengyu Electric Appliance Co., Ltd. understands the importance of quality in these connections and provides top-tier wiring solutions designed to withstand the high temperatures, vibrations, and continuous use typical in foodservice environments.

As an R&D-driven company, Cixi Tengyu Electric Appliance Co., Ltd. continuously innovates to improve the durability, safety, and efficiency of their wiring harnesses. The company is known for its ability to customize solutions based on the specific needs of steak machine manufacturers, ensuring that each wiring harness is tailored to the precise requirements of the equipment. By focusing on cutting-edge technology and materials, Cixi Tengyu Electric Appliance Co., Ltd. ensures that their products are not only functional but also cost-effective and sustainable. This commitment to innovation has allowed the company to maintain a significant market presence, with a 75%+ share of the global electrical wiring harness market.

The Role of R&D in Enhancing Wiring Harness Design

Research and development (R&D) play a pivotal role in the design and improvement of wiring harnesses used in steak machines. As technology advances and consumer demands evolve, the complexity of electrical systems in steak machines also increases. Cixi Tengyu Electric Appliance Co., Ltd. leverages its robust R&D capabilities to stay ahead of the curve by designing wiring harnesses that meet the latest industry standards while also addressing emerging needs for energy efficiency, flexibility, and enhanced functionality.

The company’s R&D team works closely with engineers to develop wiring harnesses that can handle the increasing power requirements of modern steak machines. These machines are now capable of performing multiple functions such as grilling, broiling, and even automatic seasoning. Each of these functions requires precise control, which is only achievable through high-quality electrical connections. By collaborating with steak machine manufacturers, Cixi Tengyu Electric Appliance Co., Ltd. is able to create customized wiring solutions that ensure smooth operation, even under high power loads and frequent use.

Cixi Tengyu Electric Appliance Co., Ltd. also places a strong emphasis on testing and refining its products through rigorous quality assurance processes. The company conducts extensive research on materials, insulation techniques, and shielding methods to guarantee that their wiring harnesses are resistant to wear and tear, as well as environmental factors such as moisture, heat, and grease. Through continuous innovation and investment in R&D, Cixi Tengyu Electric Appliance Co., Ltd. has maintained its position as a leading supplier of wiring harnesses for the foodservice and industrial sectors.

Ensuring Quality Management in High-Volume Production

Quality management is a cornerstone of Cixi Tengyu Electric Appliance Co., Ltd.'s operations, especially given the company’s scale of production and global market presence. With over 500 product categories and the capacity to produce over 600 million pieces of wiring harnesses per year, maintaining high standards of quality is essential to meeting the diverse needs of steak machine manufacturers and other clients across various industries. The company’s commitment to quality is reflected in its comprehensive production process, which includes stringent testing, regular audits, and continuous monitoring of production lines.

One of the key aspects of Cixi Tengyu Electric Appliance Co., Ltd.'s quality management system is its focus on material sourcing. By working with trusted suppliers and using only the highest-quality materials, the company ensures that its Steak Machine Wiring Harness meet industry standards for electrical conductivity, insulation, and durability. Additionally, the company employs advanced manufacturing technologies, such as automated assembly lines and real-time quality control monitoring, to ensure that each wiring harness is built to last and performs consistently in real-world conditions.

In addition to its manufacturing capabilities, Cixi Tengyu Electric Appliance Co., Ltd. places a strong emphasis on employee training and development. The company invests in regular training programs to ensure that its team is well-versed in the latest industry trends, safety protocols, and quality standards. By fostering a culture of excellence and continuous improvement, Cixi Tengyu Electric Appliance Co., Ltd. ensures that each product leaving its production facilities meets the highest levels of performance, reliability, and safety.

With a market share of 75%+ in the electrical wiring harness sector, Cixi Tengyu Electric Appliance Co., Ltd. has become a trusted partner for manufacturers in a variety of industries, including automotive, home appliances, and, of course, the foodservice industry. By combining cutting-edge R&D, efficient production methods, and rigorous quality management practices, the company continues to lead the way in providing exceptional wiring harness solutions.

中文简体

中文简体