Electric Oven Electrical System Overview

An electric oven is a kitchen appliance that uses electricity to heat food and is widely used in both home and commercial kitchens. The working principle of an electric oven is that the electric heating element converts electrical energy into heat, reaches a predetermined temperature, and evenly transfers it to the food to complete the cooking process. To achieve this function, the electric oven's electrical system is crucial, and the electric oven wiring harness is a key component that connects these electrical components, ensures stable current transmission, and ensures safe and efficient operation of the appliance.

The electric oven's electrical system includes several key components, such as the heating element, thermostat, control panel, power cord, fan, and safety switch. These components are connected and coordinated through the electric oven wiring harness. The heating element is the core of the electric oven, heating the food to a high temperature through electric current. The thermostat monitors the temperature inside the oven in real time and adjusts the power output of the heating element according to the set temperature, ensuring stable operation within the predetermined temperature range.

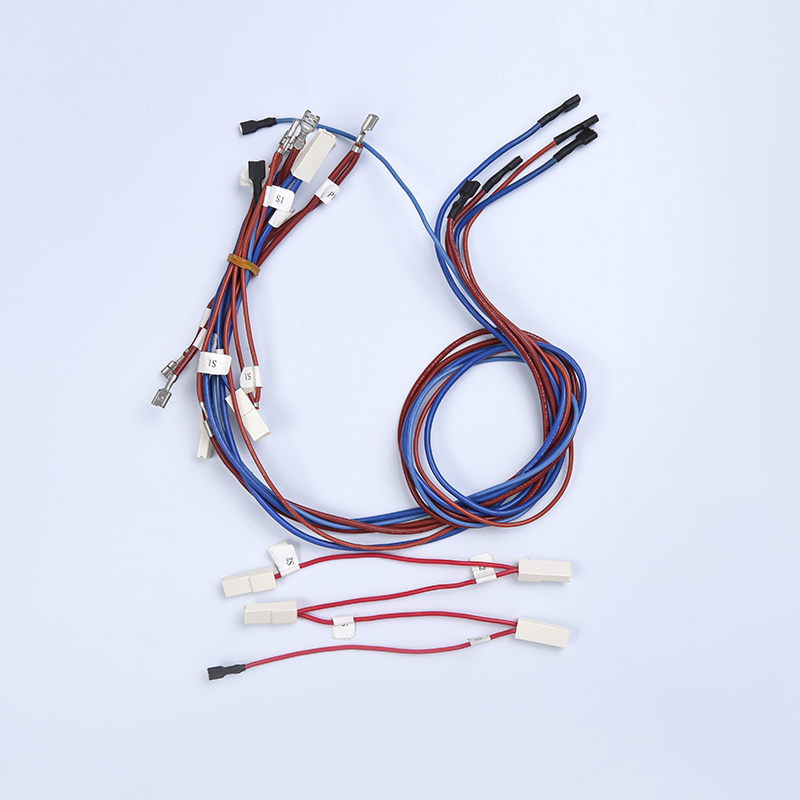

The electric oven wiring harness's primary function is to effectively connect these electrical components and ensure safe current transmission. Because electric ovens operate at high temperatures for extended periods, their electrical wiring components must possess excellent high-temperature resistance. These components must be flexible enough to accommodate the compact interior of the oven and prevent equipment malfunctions caused by wire damage or poor contact.

The temperature control system of an electric oven is particularly crucial. The thermostat monitors the oven's internal temperature in real time and sends commands to the heating elements through the electric oven wiring harness. If the temperature exceeds the set range, the thermostat shuts off the heating elements to prevent overheating and energy waste. The safety of an electric oven is closely linked to the quality of the wiring harness. Any wiring error can lead to electrical failure, overheating, or even fire. Therefore, ensuring the stability and safety of the wiring harness during design and production is crucial.

Electric Oven Wiring Harness Design and Function

The design requirements for the electric oven wiring harness are extremely high. It must not only provide excellent electrical performance but also withstand the high temperatures of the oven's interior for extended periods. Key factors in designing electrical wiring harnesses include material selection, structural rationality, and safety assurance.

Material Selection: Electric ovens typically operate at high temperatures, especially when baking, when the heating elements and oven walls can reach temperatures exceeding 200°C. Therefore, the materials used in electric oven wiring harnesses must possess excellent high-temperature resistance. High-temperature-resistant silicone-coated copper wire is commonly used due to its excellent thermal stability, corrosion resistance, and flexibility. Furthermore, the insulation material used for the wires must be both age-resistant and heat-resistant to prevent electrical failures in high-temperature environments.

Structural Design: Electric ovens have a relatively compact interior, and the layout of electrical components is complex. To prevent interference with the wiring and contact with high-temperature components, the wiring harness design is crucial. A proper layout not only ensures stable current transmission but also prevents short circuits or failures caused by friction or poor contact between wires. Therefore, when designing electrical wiring harnesses, designers typically implement appropriate insulation and protective measures to ensure that each wire maintains a safe distance from other components.

Safety: As a high-temperature appliance, the safety of the electric oven's electrical system is paramount. Electric oven wiring harnesses must comply with stringent international safety standards, such as UL and CE certifications. These certifications ensure that electrical wiring components possess excellent insulation, high-temperature resistance, and overload resistance, ensuring stable electrical transmission in high-temperature operating environments and preventing safety hazards such as short circuits, overloads, and fires. Regular quality inspections and tests ensure that each electrical wiring component remains safe and efficient over the long term.

During the production of electric ovens, Cixi Tengyu Electric Appliance Co., Ltd. leverages over two decades of technological expertise and advanced automated production equipment to rigorously control every step, ensuring that the design, production, and quality inspection of electric oven wiring harnesses meet the highest industry standards. Cixi Tengyu Electric Appliance Co., Ltd. provides customized design and production services tailored to individual customer needs, ensuring the efficient and safe operation of the electric oven's electrical system.

Electric Oven Wiring Harness Production and Common Troubleshooting

The production of electric oven wiring harnesses relies on high-precision automated equipment and rigorous quality control processes to ensure the quality and precision of each wiring component. Modern production lines have significantly improved the efficiency of electrical wiring harness production, while ensuring consistent and stable product quality.

During the production process, electric oven wiring harnesses undergo numerous rigorous tests and inspections. Common tests include high-temperature resistance, current-carrying capacity, insulation performance, and corrosion resistance. These tests effectively ensure that the electrical wiring harnesses can operate stably under high-temperature and long-term operating conditions, reducing the likelihood of failure.

Despite increasingly sophisticated manufacturing processes, common problems with electric oven wiring harnesses can still occur in actual use. Here are some typical problems and their troubleshooting methods:

Temperature control failure or uneven heating: If the oven's temperature control system fails or the heating element fails to heat food evenly, it's usually due to loose or aged wiring in the harness, resulting in unstable current flow. Inspect the wiring harness to ensure that each wire is securely connected and free of breakage or poor contact. If any wires or connectors are damaged, replace them promptly.

Device Failure to Start or Displays a Fault: If the oven fails to start properly or displays an error on the control panel, it may be due to a problem with the power cord or circuit board wiring. Check the power connector and wiring for tight connections, ensuring there are no short circuits or loose wires.

Overheat Protection Failure: The oven's overheat protection function is a critical safety mechanism that prevents overheating from causing fire or damage. If the overheat protection system fails, it's usually due to a faulty electrical connection in the oven wiring harness, preventing the signal from transmitting properly. Check for loose or deteriorating wiring and replace if necessary.

Regular maintenance and inspection are key to extending the lifespan and ensuring the safety of your oven. Promptly identifying and correcting potential wiring problems can effectively reduce equipment failures and improve operational efficiency.

Cixi Tengyu Electric Appliance Co., Ltd., with its advanced production technology and strict quality control, manufactures electric oven wiring harnesses that are widely used worldwide and have earned the trust of numerous customers for their outstanding performance in high-temperature and high-load environments. Through continuous innovation and product improvement, Cixi Tengyu Electric Appliance Co., Ltd. provides safe, efficient and reliable electrical wiring solutions to users around the world.

中文简体

中文简体