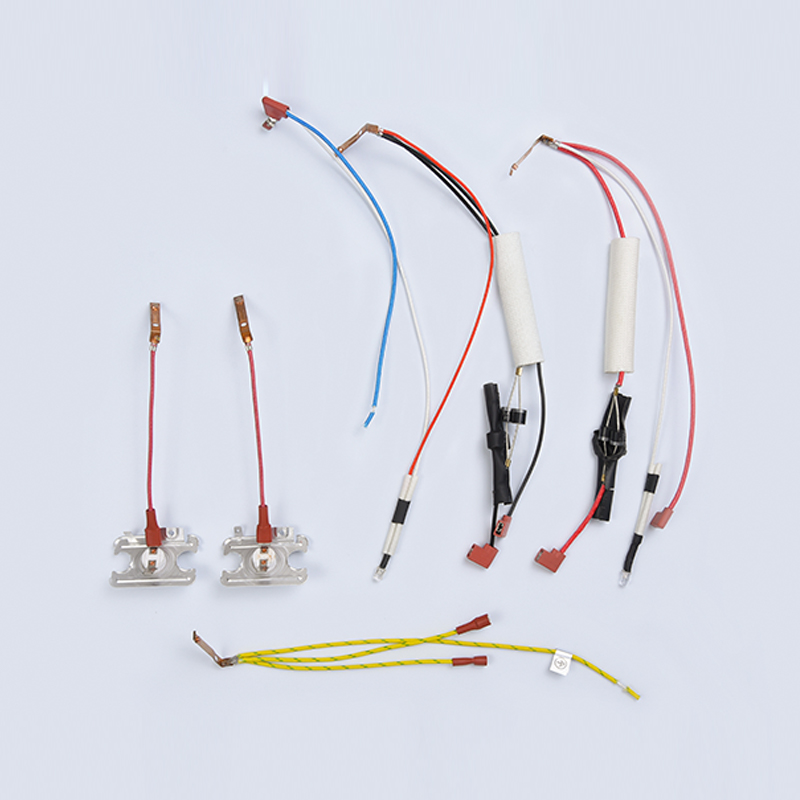

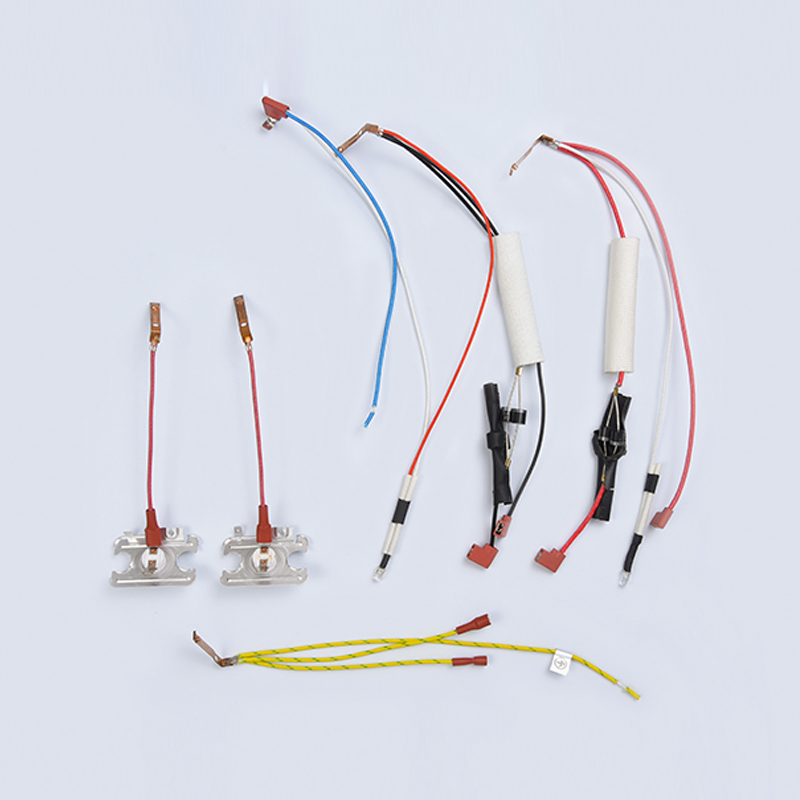

Function and Composition of Electric Hot Pot Wiring Harness

The electric hot pot wiring harness is a key component of the electric hot pot's internal electrical connections. It ensures a stable connection and safe current transmission between the power supply and the hot pot's various electrical components (such as the heating element, thermostat, and display panel). The wiring harness not only provides connectivity during electrical operation but also plays a crucial role in protecting the electrical system from external factors. For household appliances like electric hot pots, the function of the wiring harness is crucial, directly impacting the product's safety, stability, and durability.

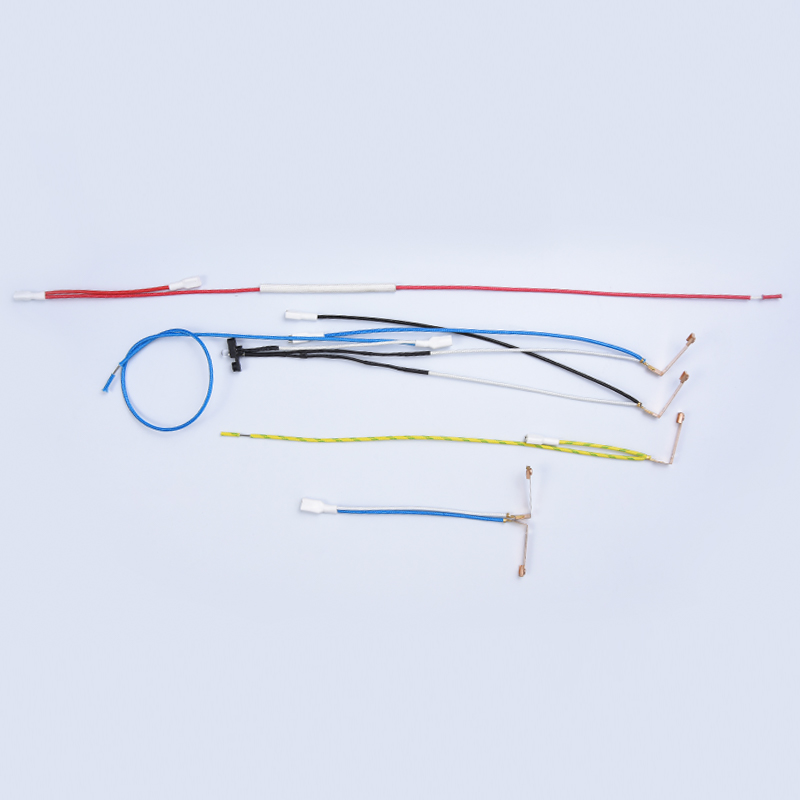

The wiring harness is relatively complex, primarily consisting of cables, connectors, thermostat connections, and a power plug and socket. The cable is the core component of the electric hot pot wiring harness, responsible for transmitting current to the various heating elements and control system. Cable selection requires consideration of voltage and current requirements. Copper or aluminum wire is typically used as the conductive material. Copper wire is the mainstream choice due to its excellent conductivity, while aluminum wire is used when cost is lower.

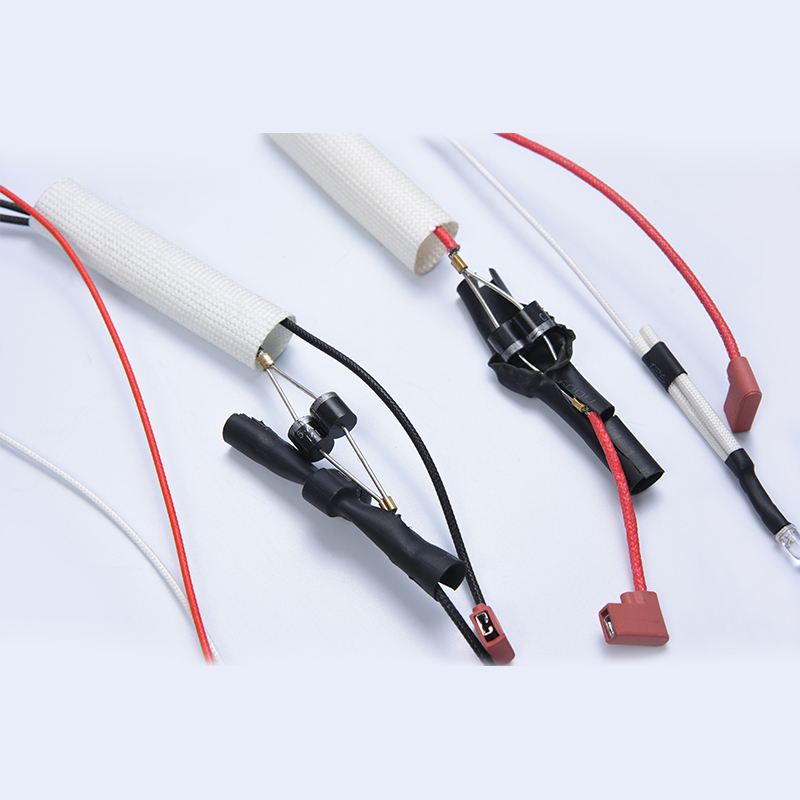

Connectors connect the various electrical components in the wiring harness. They ensure good contact between electrical components, reducing the risk of poor contact or unstable current transmission. Connector design must balance durability and safety to prevent electrical hazards caused by aging or loosening. The thermostat connection in the wiring harness is crucial. The thermostat is the core component that controls the heating of the electric hot pot and must be connected to the heater and power system. The wiring harness must ensure efficient connection between the thermostat and the heating element to ensure stable and safe heating temperatures.

The power plug and socket connect the electric hot pot to the external power source. The other end of the wiring harness connects to the external power source through the plug. The quality of the plug and socket directly affects the safety of the electric hot pot during use. Modern electric hot pot plugs are often designed with waterproofing and overload protection in mind to enhance overall safety and durability.

Electric hot pot wiring harness technical requirements and safety

The technical requirements for electric hot pot wiring harnesses primarily focus on ensuring electrical safety, improving durability, and adapting to diverse environmental conditions. Because electric hot pots are high-power household appliances, their wiring harnesses must be able to handle high currents and temperature fluctuations, ensuring electrical stability during use and avoiding potential risks such as short circuits and leakage.

When operating, especially during the heating process, the internal temperature of an electric hot pot can rise rapidly, even reaching hundreds of degrees Celsius. Therefore, the cables and insulation materials used in the electric hot pot wiring harness must be heat-resistant. Common high-temperature-resistant materials include silicone and high-temperature PVC. These materials maintain stable performance in high-temperature environments and will not age or melt due to prolonged heating.

Electric hot pot wiring harnesses directly involve electrical transmission, so their insulation must effectively isolate the current to prevent leakage and electric shock. Commonly used insulation materials include PVC, silicone, and rubber. These materials not only provide excellent electrical insulation but also effectively resist environmental corrosion, such as moisture and dust. Furthermore, the insulation material must be highly resistant to mechanical stress to prevent damage from bending or stretching during long-term use.

Durability of the wiring harness is also a key technical requirement. During use, electric hot pot wiring harnesses are subject to frequent heating and cooling cycles, requiring them to withstand significant mechanical stress. Long-term temperature fluctuations and frequent electrical switching can cause material degradation, cracking, and deformation. Therefore, the wiring harness design must consider the material's wear resistance, corrosion resistance, and aging resistance to ensure it maintains good electrical connectivity and mechanical properties even after extended use.

The waterproof performance of electric hot pot wiring harnesses is also becoming an increasingly important consideration in safety design. Due to the humid nature of the kitchen environment, wiring harnesses may be exposed to water vapor and liquid splashes, necessitating measures to prevent moisture from entering the electrical system. Waterproofing typically involves the use of seals and the design of waterproof plugs and sockets to protect the electrical components from the effects of water vapor and moisture.

Electric Hot Pot Wiring Harness Standards and Materials

The design and production of electric hot pot wiring harnesses must not only meet functional requirements but also comply with relevant electrical safety standards and material selection specifications. As a company with over 20 years of experience, Cixi Tengyu Electric Appliance Co., Ltd. has accumulated extensive experience in the design, manufacturing, and quality control of electric hot pot wiring harnesses. Leveraging its internationally advanced production technology and scientific management system, Cixi Tengyu Electric Appliance Co., Ltd. ensures that its electric hot pot wiring harnesses consistently meet domestic and international quality standards and satisfy market requirements for safety, environmental friendliness, and durability.

Adhering to the business philosophy of "people-oriented, innovation-driven development," Cixi Tengyu Electric Appliance Co., Ltd. prioritizes not only technological innovation but also strict quality control and production process management. The design and manufacturing of its electric hot pot wiring harnesses comply with a range of international and domestic safety certifications, such as UL, CE, and CCC. These certifications guarantee product safety and reliability in the global market. Cixi Tengyu Electric Appliance Co., Ltd.'s products undergo rigorous testing and review, ensuring that each wiring harness possesses excellent electrical performance and safety, capable of withstanding extreme environments such as high temperatures and high currents.

Cixi Tengyu Electric Appliance Co., Ltd. prioritizes environmental protection and sustainable development in its material selection, prioritizing high-performance conductors and insulation materials. The company extensively uses copper wire as a conductive material, as copper offers excellent conductivity and corrosion resistance, ensuring efficient current transmission. To ensure the high-temperature resistance and insulation performance of wiring harnesses, Cixi Tengyu Electric Appliance Co., Ltd. uses high-temperature resistant PVC, silicone, and rubber. These materials not only provide excellent electrical isolation but also effectively withstand the high-temperature fluctuations and mechanical stresses associated with long-term use. Cixi Tengyu Electric Appliance Co., Ltd. also pays special attention to the environmental performance of its materials, selecting non-toxic and recyclable materials to comply with increasingly stringent global environmental regulations and consumer demands.

Cixi Tengyu Electric Appliance Co., Ltd. has an experienced R&D team dedicated to the application of new materials and processes. Under a strict quality management system, each wiring harness meets world-class manufacturing standards. By optimizing production processes, improving equipment precision, and strictly controlling production procedures, the company ensures that every wiring harness product undergoes meticulous testing before shipment, meets international safety standards, and exhibits high durability and a long lifespan.

To establish Cixi Tengyu Electric Appliance Co., Ltd. as a globally renowned brand, the company continuously enhances its R&D capabilities and technological innovation, striving to meet the needs of global customers with high-quality products and exceptional service. The company not only focuses on the domestic market but also actively explores international markets, with its products exported overseas and earning the trust and praise of both domestic and international customers. Through continuous technological innovation and strict quality control, Cixi Tengyu Electric Appliance Co., Ltd. is committed to providing global consumers with safer, more environmentally friendly, and more efficient electric hot pot wiring harness products, striving to elevate the brand to world-class status.

中文简体

中文简体