Function and Structure of the Electric Grill Harness

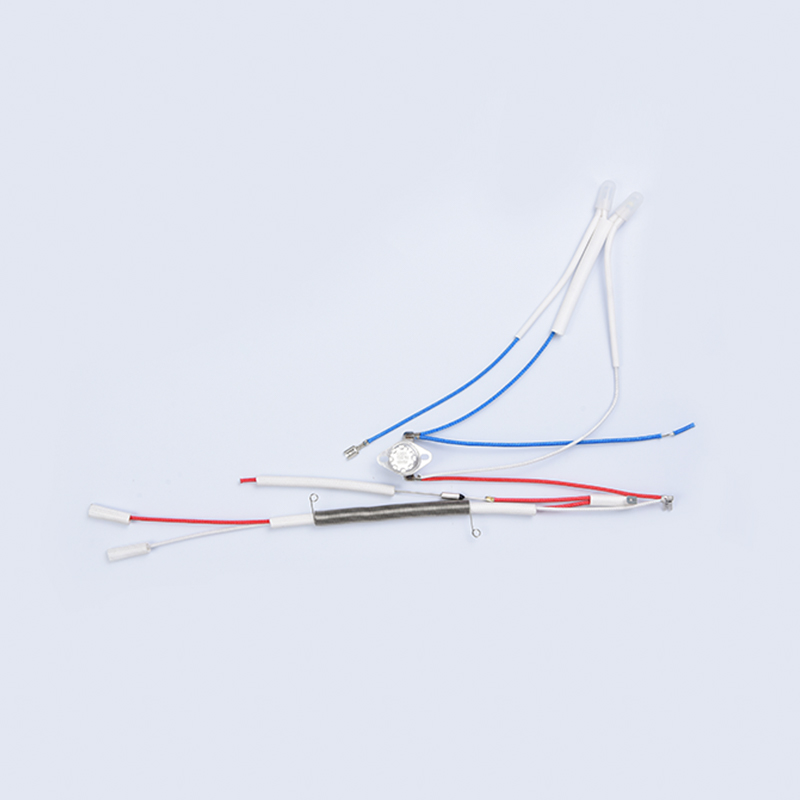

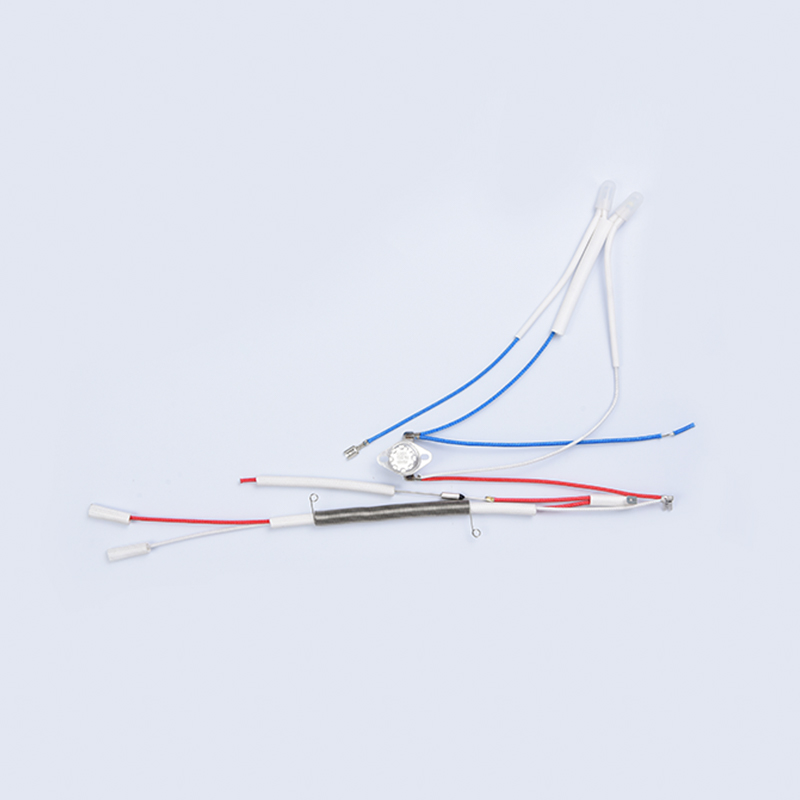

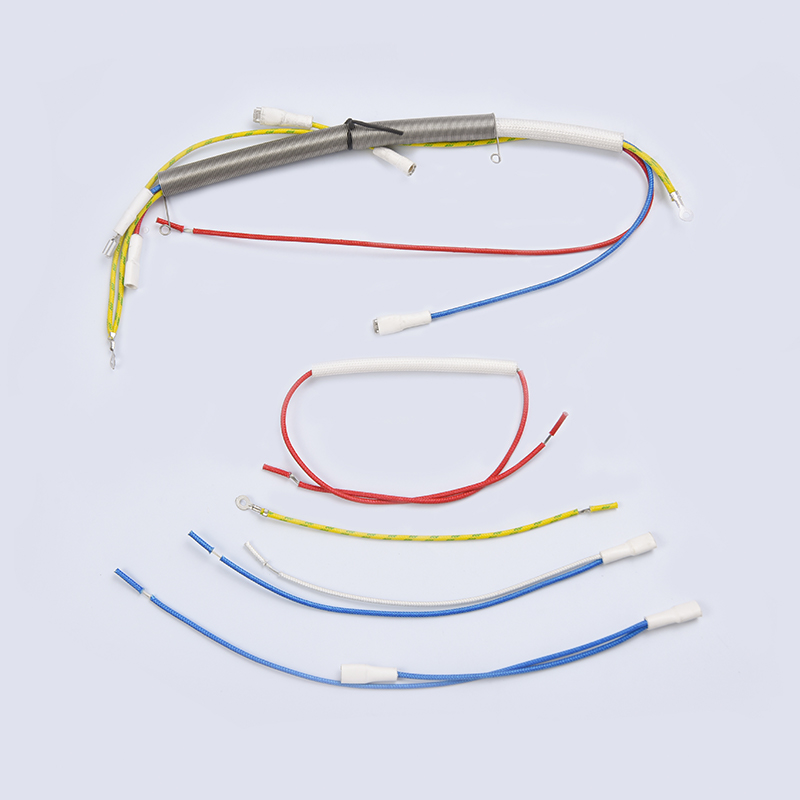

As efficient kitchen appliances, electric grills are widely used in homes, restaurants, and hotels, providing convenient grilling and cooking functions. The electrical system within an electric grill requires a wiring harness to connect various electrical components (such as the heating element, thermostat, and fan) to ensure proper operation and safe use. The wiring harness plays a crucial role in electric grills, not only ensuring the proper transmission of current but also ensuring the stability and safety of the grill in high-temperature, high-current environments.

The electric grill harness is a crucial component of the electric grill's internal electrical system, connecting the power supply to the various electrical components and ensuring the proper transmission of electrical signals and current. The primary operating principle of an electric grill is to convert electrical energy into heat through the heating element, which is then used to grill and cook food. Therefore, the wiring harness must transmit power to multiple components, including the heating element, fan, and thermostat, while also ensuring stable and secure electrical connections.

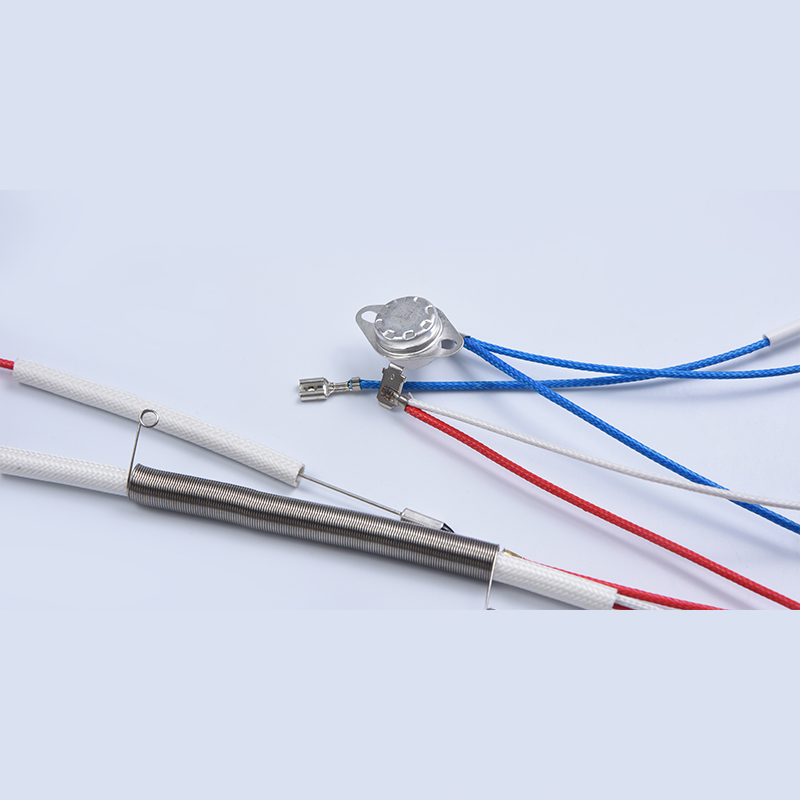

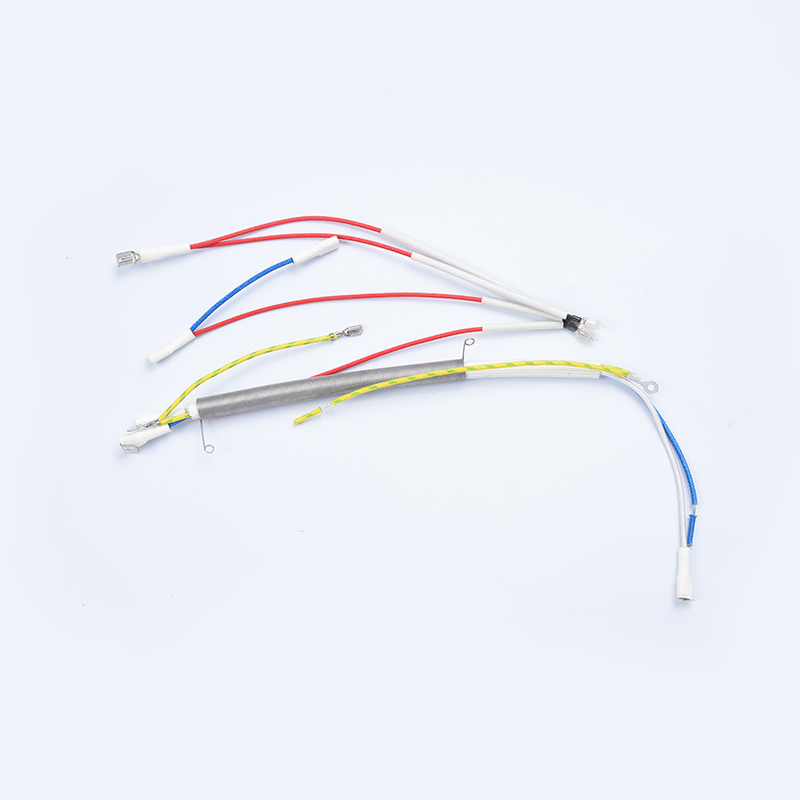

Cable: The core component that transmits electrical current. Typically made of copper wire, it offers strong conductivity and oxidation resistance, ensuring stable current flow. Connectors and Terminals: Used to connect cables to components such as heating elements, thermostats, and fans, ensuring reliable and stable electrical connections.

Thermostat Connections: Connect the thermostat to the heating element, regulating the oven's operating temperature and ensuring food is cooked within the appropriate temperature range.

Power Plug and Socket: Connect the power supply to the oven, ensuring stable power supply.

Technical Requirements for Electric Grill Harness

The operating environment of electric grills requires wiring harnesses to meet several technical requirements, especially under high-temperature and high-current conditions. The performance and safety of the wiring harness are particularly important.

High-temperature resistance: The heating element of an electric grill can reach high temperatures during operation, typically exceeding 200°C. The cables and insulation materials in the wiring harness must be highly resistant to high temperatures to ensure long-term stable operation without deformation, melting, or damage. Commonly used high-temperature-resistant materials include silicone and high-temperature-resistant PVC.

Good Insulation: Due to the high current flow within electric ovens, wiring harnesses must possess excellent insulation properties to prevent safety hazards such as current leakage or short circuits. Commonly used insulation materials include PVC, rubber, and silicone. These materials effectively isolate electrical components from the external environment, ensuring safety during use.

Aging Resistance: During operation, wiring harnesses are exposed to heat, humidity, and mechanical stress for extended periods of time. Therefore, their materials must be resistant to aging to prevent embrittlement or failure due to prolonged use. High-quality wiring harness materials offer a long service life and maintain stable performance in high-temperature and high-humidity environments.

High Current Carrying Capacity: Electric ovens operate at high heating power, requiring wiring harnesses to possess strong current-carrying capacity to prevent overheating or damage due to excessive current. Copper wire is a common conductive material with low resistance and excellent conductivity, ensuring efficient current conduction.

Corrosion Resistance: During use, especially in high-humidity environments, the wiring harness may corrode. Therefore, its material must be corrosion-resistant to prevent oxidation and potential contact problems or malfunctions.

Electric Grill Harness Material Selection and Industry Standards

The quality of the electric grill harness is directly related to the safety, performance, and lifespan of the electric grill. With the continuous development of the electric grill market, the material selection, design, and production processes of the wiring harness are constantly innovating to meet the demands of high temperatures, high currents, and intelligent operation. Cixi Tengyu Electric Appliance Co., Ltd., leveraging over 20 years of technological expertise and rigorous quality control, is committed to providing customers with high-quality electric grill harnesses that meet international standards and meet the needs of global consumers.

In the production of electric grill harnesses, Cixi Tengyu Electric Appliance Co., Ltd. utilizes internationally advanced production technologies and high-quality raw materials to ensure the stability and safety of each wiring harness in high-temperature environments. Leveraging its strong R&D team and production expertise, the company selects high-quality materials that meet international standards such as UL and CE certification, such as high-temperature-resistant copper wire and silicone insulation. This ensures the electric grill harness possesses excellent conductivity, insulation, and high-temperature resistance, meeting the safety and efficiency requirements of modern electric grills.

Cixi Tengyu Electric Appliance Co., Ltd. understands that the heating elements of electric grills generate significant heat during operation, requiring the wiring harness to be highly conductive and heat-resistant. The company selects **copper wire** as its primary conductor material. Copper wire not only offers excellent conductivity but also possesses excellent oxidation and corrosion resistance, enabling it to conduct high currents reliably and for extended periods. Cixi Tengyu Electric Appliance Co., Ltd. also pays particular attention to copper wire quality management, ensuring that each wire complies with international electrical standards and provides a reliable electrical connection.

The insulation material of the electric grill harness is crucial. Cixi Tengyu Electric Appliance Co., Ltd. uses silicone and high-temperature-resistant PVC as the insulation layer. Silicone has excellent high-temperature resistance and can withstand the high temperatures (over 200°C) generated by electric grills, effectively preventing the wiring harness from softening or aging under high temperatures. While PVC is suitable for conventional electrical products, Cixi Tengyu Electric Appliance Co., Ltd. also ensures that it has sufficient aging and corrosion resistance to withstand the long-term high-temperature environments encountered during electric grill operation.

Cixi Tengyu Electric Appliance Co., Ltd. also strictly selects materials for the connectors and joints of electric grill harnesses, typically using copper alloy and gold plating to prevent oxidation and poor contact under high current conditions, ensuring stable current conduction. High-quality connectors and joints not only improve electrical connection reliability but also extend the life of the wiring harness. Cixi Tengyu Electric Appliance Co., Ltd. strives for excellence in this area, ensuring that each joint can withstand the test of high temperatures and currents through precision machining and rigorous testing.

As a company with over 20 years of experience, Cixi Tengyu Electric Appliance Co., Ltd. understands the importance of product quality to brand reputation and customer trust. The company strictly controls every step of the production process, ensuring that every electric grill harness meets international safety standards and has obtained multiple certifications, including UL, CE, and RoHS. Cixi Tengyu Electric Appliance Co., Ltd. maintains a comprehensive quality management system, employing leading international standards throughout its entire process, from raw material procurement to production and processing, and finally to final quality testing, to ensure the safety and stability of its products.

UL Certification: Cixi Tengyu Electric Appliance Co., Ltd.'s electric grill harnesses are UL certified, signifying compliance with US electrical safety standards and strong resistance to fire and electrical faults.

CE Certification: CE certification serves as a passport for Cixi Tengyu Electric Appliance Co., Ltd.'s electric grill harnesses to enter the European market, certifying compliance with EU safety and electromagnetic compatibility requirements.

RoHS Certification: In response to global environmental trends, Cixi Tengyu Electric Appliance Co., Ltd. has also obtained RoHS certification, ensuring that the production of the electric grill harnesses is free of hazardous substances, in compliance with environmental regulations, and meeting consumer demand for green and safe products.

中文简体

中文简体