Function and Components of an Electric Cooker Harness

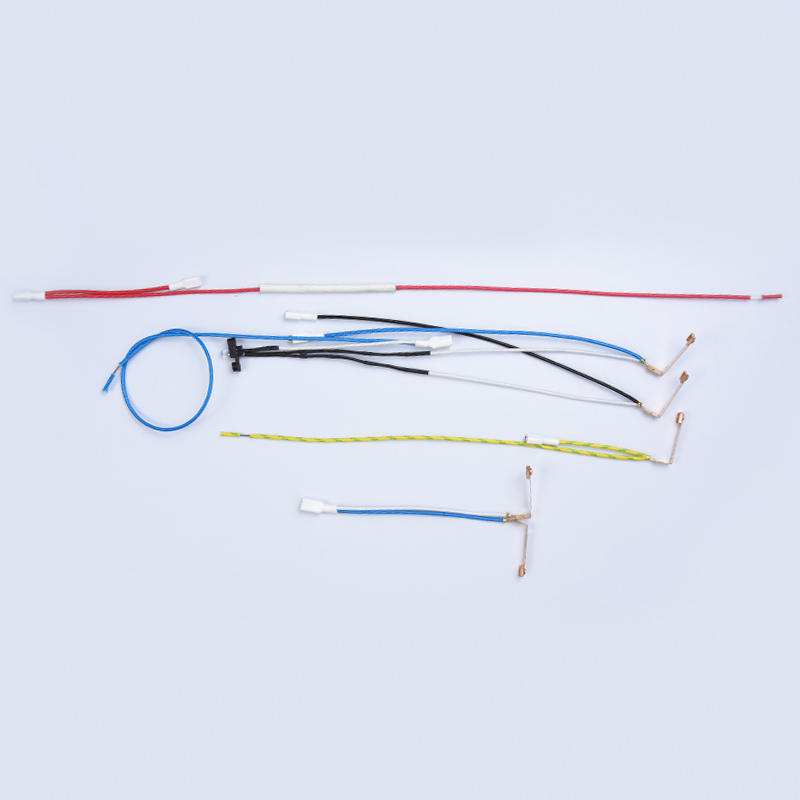

As an indispensable appliance in modern kitchens, electric rice cookers offer efficient and convenient heating and cooking functions. To ensure the safety, stability, and efficiency of rice cookers during daily use, their internal electrical connection system—the wiring harness—plays a crucial role. The electric cooker harness is a crucial component that connects the power source to various electrical components (such as the heater, thermostat, and display), and its quality directly impacts the performance and safety of the rice cooker.

The electric cooker harness is the electrical transmission system within the rice cooker, responsible for connecting the power source to the internal electrical components and ensuring stable current transmission. The wiring harness's role is more than just electrical connection; it also needs to provide a stable and secure electrical connection in high-temperature and high-humidity environments to prevent electrical failures, short circuits, and overheating. The rice cooker's operating principle primarily relies on heating elements (such as the heating plate and heating element) to convert electrical energy into heat to heat food, and the wiring harness is responsible for ensuring smooth current transmission between these components.

Cable: The core component that conducts electricity, typically made of copper wire to ensure good conductivity and stable current transmission.

Connectors: Connect the cable to the various components within the rice cooker, ensuring a secure electrical connection and preventing poor contact or unstable current flow.

Thermostat: Connects the thermostat to the heating element, regulating the heating temperature and ensuring the rice cooker operates at the set temperature.

Power Plug & Socket: Connects the power supply to the rice cooker, ensuring it is securely connected to a power source.

Technical Requirements for Electric Cooker Harnesses

Electric cooker harnesses must meet several stringent technical requirements to ensure electrical safety, durability, and stability, especially in harsh environments such as high temperature, high humidity, and frequent on/off cycles.

High-temperature resistance: Electric cookers generate high temperatures during operation, especially the heating element, which can exceed 200°C. Therefore, the cables and insulation materials in the wiring harness must possess excellent high-temperature resistance to maintain stable operation in high-temperature environments and avoid material degradation or melting due to overheating. Commonly used high-temperature-resistant materials include silicone and high-temperature-resistant PVC.

Good Insulation: Electric cooker harnesses must possess excellent insulation properties to prevent current leakage and electrical faults. The insulation layer must meet electrical safety standards to prevent the wiring harness from contacting other metal parts or the external environment, thereby preventing electrical hazards. Common insulation materials include PVC, rubber, and silicone, which effectively isolate current and prevent electric shock.

Moisture Resistance and Waterproofing: Rice cookers are often used in humid kitchen environments, where moisture vapor can penetrate the electrical system, causing short circuits or other electrical failures. Therefore, the wiring harness design must consider water resistance. Waterproof seals, sealed connectors, and moisture-resistant materials can effectively prevent moisture from damaging the wiring harness.

High Current Carrying Capacity: Rice cookers have high heating power, so the wiring harness must have a high current carrying capacity to ensure it does not overheat or become damaged due to excessive current during prolonged use. Cable specifications are typically selected based on voltage and current requirements. Copper wire is a common conductive material due to its excellent conductivity and low resistance.

Aging Resistance and Durability: During the use of an electric rice cooker, the wiring harness undergoes frequent temperature fluctuations of heating and cooling. Long-term use may cause material aging, embrittlement, or cracking. Therefore, the wiring harness must have excellent aging resistance and be able to maintain stable performance under repeated temperature fluctuations and mechanical stress.

Electric Cooker Harness Material Selection and Industry Standards

Material selection is crucial to ensuring the performance and safety of an electric cooker harness. The wiring harness material must comply with national and international electrical safety standards and meet environmental requirements.

Conductor Material: The conductor of an electric cooker harness is typically copper wire. Copper has excellent conductivity, reducing current loss and uneven heating rates. Copper wire is also highly corrosion-resistant, maintaining stable electrical performance over long-term use. While some low-cost products may use aluminum wire, copper remains the preferred material for high-quality electrical connections.

Insulation: Insulation is a key element in the design of an electric cooker harness. Common materials include PVC, silicone, and rubber. PVC offers excellent insulation and corrosion resistance, making it suitable for standard electrical environments. Silicone, on the other hand, offers strong heat resistance and stability in high-temperature environments. Rubber offers advantages in flexibility and abrasion resistance, making it suitable for wiring harnesses subject to frequent flexing.

Connector and Connector Materials: Connectors ensure a good connection between electrical components. Common materials include gold- or silver-plated copper alloys, which improve conductivity and prevent poor contact due to oxidation or wear.

Standards and Certifications: Electric cooker harnesses must comply with international and regional electrical safety standards, such as UL in the United States, CE in the European Union, and CCC in China. These certifications ensure compliance with safety standards and prevent electrical accidents caused by design flaws or material defects. With increasingly stringent global environmental regulations, more and more companies are focusing on the environmental friendliness of their materials, choosing non-toxic, recyclable materials that comply with environmental directives such as RoHS.

Market Trends and Challenges

With the continuous innovation and advancement of the functionality of rice cookers and other home appliances, the demand for wiring harnesses is becoming increasingly diverse. They must not only meet basic electrical connection requirements but also adapt to emerging trends such as intelligence, high efficiency, and energy conservation. In this process, Cixi Tengyu Electric Appliance Co., Ltd., leveraging its extensive industry experience and superior technical capabilities, remains at the forefront of the industry, providing high-quality electric cooker harnesses that meet market demands.

Cixi Tengyu Electric Appliance Co., Ltd. understands the diverse market demands and offers customized design services, tailoring electric cooker harnesses to meet specific needs and specifications. This customization allows Cixi Tengyu Electric Appliance Co., Ltd. to design the most optimal wiring harness solution based on the diverse functional requirements, dimensions, and operating environments of rice cookers.

Cixi Tengyu Electric Appliance Co., Ltd. prioritizes quality control as its core competitive advantage. The company maintains a strict quality management system, rigorously controlling every step from design to production to ensure that every electric cooker harness complies with relevant industry standards and international certifications. Cixi Tengyu Electric Appliance Co., Ltd.'s electric cooker harnesses undergo rigorous testing and inspection to ensure stable electrical performance in harsh environments such as high temperature, humidity, and long-term operation. Each harness undergoes multiple performance tests, including high-temperature resistance, insulation, and corrosion resistance, to ensure safety and reliability in long-term use.

中文简体

中文简体