Deep Fryer Electrical System Overview

A deep fryer is a type of kitchen equipment widely used in the food service industry. It heats oil to quickly fry food, and is widely used for frying French fries, chicken wings, dumplings, and other dishes. The deep fryer's operating principle is simple and efficient: an electric heating element heats the oil to the desired temperature before the food is placed in the oil for frying. The deep fryer's internal electrical system determines the deep fryer's operational stability and safety. The deep fryer wiring harness is a core component, connecting all electrical components and ensuring smooth power and signal transmission.

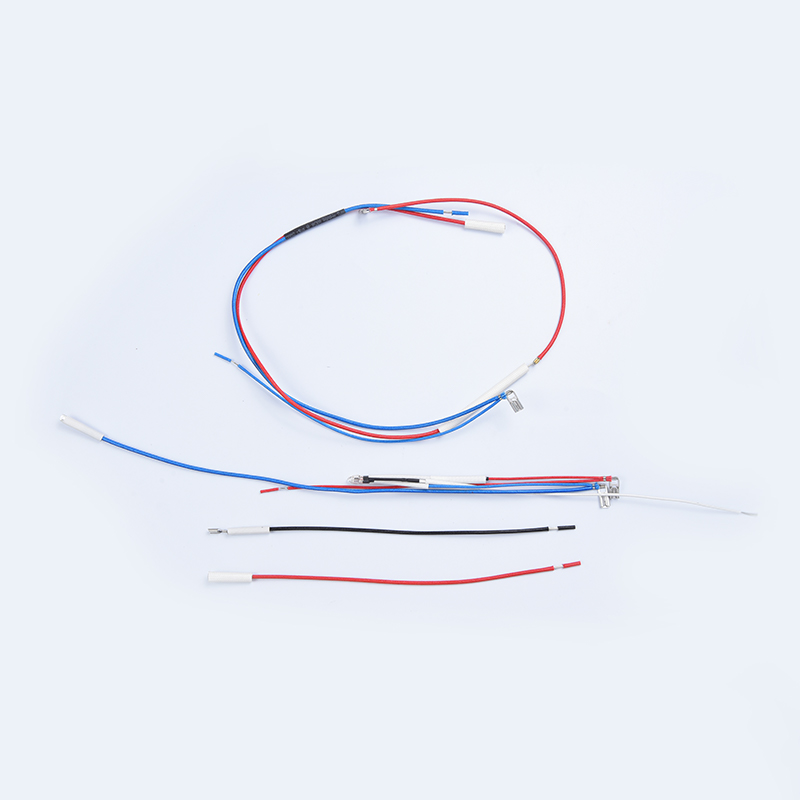

The deep fryer's electrical system includes the heating element, power cord, temperature sensor, fan, circuit board, control panel, and other components. These components are connected and coordinated via the deep fryer wiring harness. The heating element is the most critical component of the deep fryer, heating the oil to the desired high temperature through electricity, while the temperature sensor monitors the oil temperature in real time to ensure it remains within a safe range. When the oil temperature is too high, a temperature sensor sends a signal to the circuit board, which then controls the operation of the heating element through the deep fryer wiring harness to prevent dangerous overheating.

The deep fryer wiring harness must not only ensure stable current transmission but also withstand the high temperatures inside the deep fryer. Oil temperatures during frying often reach over 180°C, requiring the electrical wiring components to be made of high-temperature-resistant materials to prevent degradation, melting, or short-circuiting under prolonged high-temperature conditions. Furthermore, deep fryers frequently cycle the heating element, making the durability of the wiring components crucial.

Companies like Cixi Tengyu Electric Appliance Co., Ltd. take these factors into consideration when designing and manufacturing deep fryer wiring harnesses, using highly heat-resistant and corrosion-resistant materials to ensure the wiring can operate stably and sustainably under high loads and temperatures. With over two decades of technological expertise, Cixi Tengyu Electric Appliance Co., Ltd. has become a leading supplier of electrical components, providing high-quality, durable, and safe wiring components that have earned high recognition from domestic and international customers.

Deep Fryer Wiring Harness Design and Function

The deep fryer wiring harness plays a crucial role in the deep fryer's electrical system. It connects all electrical components, ensuring stable current and signal transmission, enabling efficient, stable, and safe deep fryer operation. When designing and producing high-quality deep fryer wiring harnesses, not only electrical performance must be considered, but also their ability to operate stably and reliably under high temperatures and high current loads. Therefore, selecting appropriate materials, ensuring proper wiring, and ensuring high safety are key design elements.

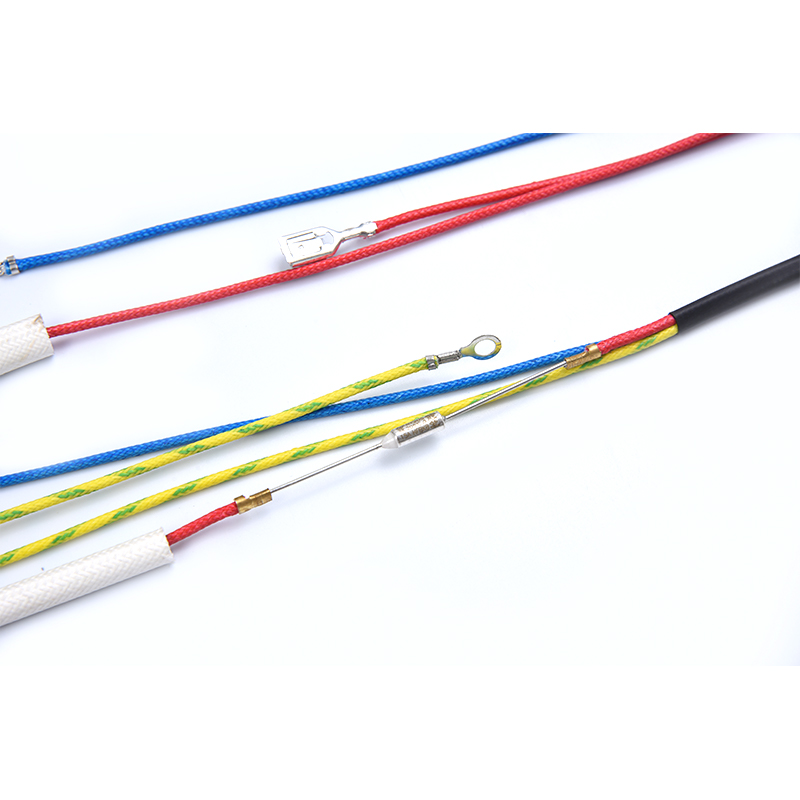

The design of the deep fryer wiring harness must take into account the high-temperature operating environment of the deep fryer. Deep fryers often operate with oil temperatures exceeding 180°C. Electrical wiring components must be constructed of high-temperature and corrosion-resistant materials to ensure stability in these environments. Commonly used materials include high-temperature silicone-coated copper wire and high-temperature resistant PVC. These materials not only withstand the effects of high temperatures but also ensure efficient and stable electrical transmission. Cixi Tengyu Electric Appliance Co., Ltd. has over 20 years of technological expertise in the electrical accessories field, particularly in the design of wiring components for high-temperature, high-load environments. Through precise design and high-quality material selection, Cixi Tengyu Electric Appliance Co., Ltd. ensures its deep fryer wiring harness can withstand long-term high temperatures and high current loads.

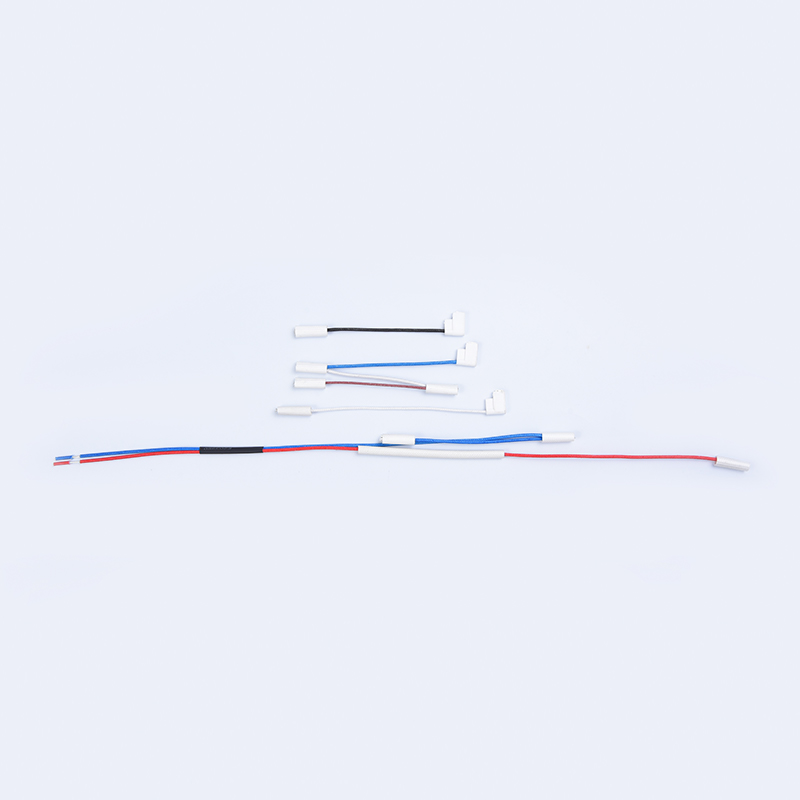

Not only does Cixi Tengyu Electric Appliance Co., Ltd.'s deep fryer wiring harness meet the requirements of high-temperature environments, it also offers customized design services. Based on the customer's specific needs and specifications, the company provides personalized design services to ensure each wiring component is precisely matched to the specific requirements of the deep fryer. Whether it's current load, wire length, or connector type, Cixi Tengyu Electric Appliance Co., Ltd. can provide tailored solutions to meet customer needs. This capability enables Cixi Tengyu Electric Appliance Co., Ltd. to provide professional technical support and product design to meet the needs of various industries, particularly in the food and beverage industry, where customized deep fryers are increasingly in demand.

In addition to material selection and custom design, the structural layout of the deep fryer wiring harness is also crucial. Deep fryers typically have a compact interior, requiring careful planning of electrical wiring to prevent wires from intertwining, rubbing, or contacting high-temperature components, potentially leading to electrical failures. Cixi Tengyu Electric Appliance Co., Ltd.'s design team carefully considers the deep fryer's internal spatial layout, precisely calculating the routing of each wire to ensure clean, organized wiring and avoid interference during current transmission. Cixi Tengyu Electric Appliance Co., Ltd. also ensures that all connectors and plugs are securely connected to enhance the reliability and stability of the wiring assembly.

Most importantly, the safety of the deep fryer wiring harness must be strictly guaranteed. As a high-temperature appliance, any failure in the electrical wiring components of a deep fryer can lead to serious safety issues, even fire or electrical accidents. Cixi Tengyu Electric Appliance Co., Ltd. places particular emphasis on product quality assurance, ensuring that every deep fryer wiring harness meets relevant international safety standards and certification requirements. All electrical wiring components at Cixi Tengyu Electric Appliance Co., Ltd. undergo rigorous quality testing, including high-temperature resistance testing, current-carrying capacity testing, and corrosion resistance testing, ensuring stable and reliable performance. The company's products have received numerous international certifications, such as UL and CE, ensuring compliance with global safety standards and meeting the needs of diverse markets.

To further ensure product quality, Cixi Tengyu Electric Appliance Co., Ltd. offers a comprehensive quality assurance system. Each batch undergoes rigorous quality inspections to prevent substandard products from entering the market. Cixi Tengyu Electric Appliance Co., Ltd.'s Deep Fryer Wiring Harness consistently leads in quality, earning the trust of domestic and international customers.

Deep Fryer Wiring Harness Production and Common Troubleshooting

The Deep Fryer Wiring Harness production process requires high-precision automated equipment to ensure the quality and precision of each wiring component. Technological advancements and modern production lines have significantly improved the production efficiency of electrical wiring components, while also ensuring product consistency and stable quality. The electrical wiring components of a deep fryer must not only provide excellent electrical transmission capabilities but also withstand high temperatures, frequent switching cycles, and corrosive environments such as oil fumes.

During the production process, deep fryer wiring harnesses undergo a series of rigorous quality inspections, including high-temperature resistance, wear resistance, and insulation testing. Quality control at every stage is crucial to ensure that the electrical wiring components can operate stably and long-term under the high loads and high temperatures of deep fryers. Test data is fed back to the production line to ensure that unqualified products are promptly removed, thereby improving overall product quality.

Although the quality of the deep fryer wiring harness has been extensively tested, some common faults may still occur during long-term use.

Uneven heating or no heating: This is usually caused by poor contact or loose wiring between the heating element and the circuit board, preventing effective current transmission. In this case, check for loose wiring and reconnect or replace any damaged parts immediately.

The device will not start or display an error: This is usually caused by a faulty power cord or circuit board wiring, preventing current from reaching the device. Check the power connector on the deep fryer wiring harness to ensure it's not short-circuited or loose.

An unresponsive control panel or temperature control failure often indicates an electrical wiring issue, possibly due to loose or damaged wiring on the circuit board, preventing signal transmission. In this case, check the wiring for security or replace any aging or damaged wiring harnesses.

To resolve these issues, deep fryer maintenance personnel can regularly inspect the wiring harness to ensure proper contact and no looseness, replacing it if necessary. Regular maintenance and servicing not only extends the life of your deep fryer but also improves equipment safety and efficiency.

Professional manufacturers such as Cixi Tengyu Electric Appliance Co., Ltd. continuously optimize the design and production processes of their deep fryer wiring harnesses, improving product quality and providing global customers with safer and more reliable deep fryer electrical wiring solutions.

中文简体

中文简体