Functional Role and Core Importance of the Water Purifier Wiring Harness in Modern Filtration Systems

The

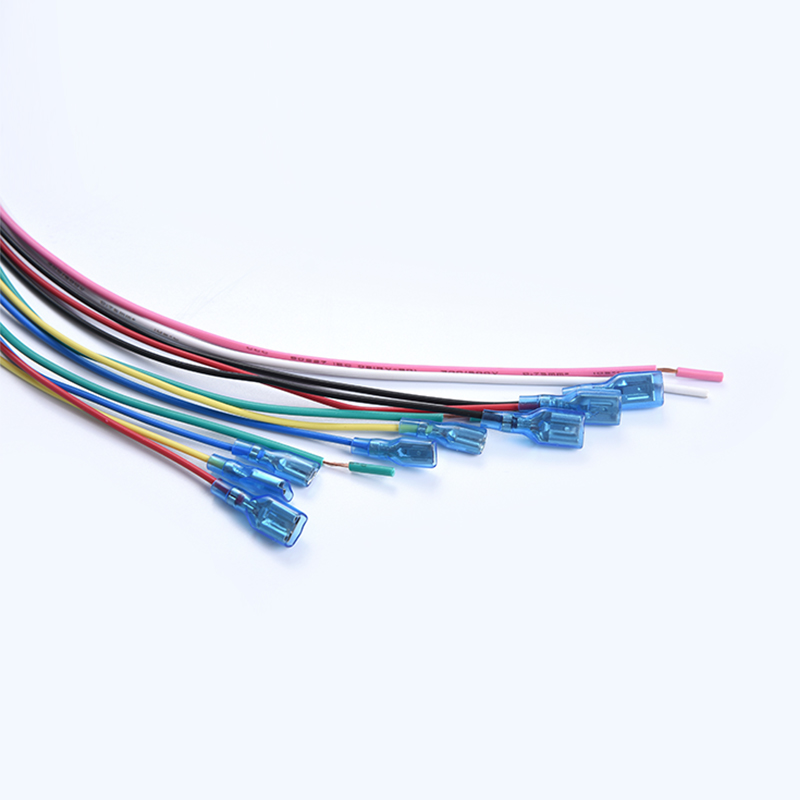

Water Purifier Wiring Harness can be defined as an organized assembly of electrical cables, connectors, terminals, and protective coverings that together form the electrical nervous system of the filtration unit. Much like how nerves transmit signals in the human body, the wiring harness distributes power and carries control signals to every critical module inside the purifier. It is not simply a collection of wires bundled together, but rather a carefully engineered network designed to handle electrical loads in a confined, moisture-prone environment where reliability is not optional but mandatory. If we imagine the purifier as a living organism, then the wiring harness functions as the circulatory system of energy and communication. The fundamental role is to provide stability, ensure efficiency, and prevent risks that could arise from improper or fragile electrical connections. While an ordinary user rarely sees this component, its absence or malfunction would render the entire purifier useless. Every button we press, every drop of purified water we receive, and every safety function that protects us from contaminated water relies on the precise and consistent functioning of the wiring harness.

At the heart of the Water Purifier Wiring Harness lies its role in distributing electrical energy to multiple subsystems. The purifier typically contains a pump to push water through membranes, a solenoid valve to control flow, a UV sterilizer for disinfection, a control board for automated decision-making, and sometimes additional modules such as TDS sensors or pressure switches. Each of these modules requires consistent electrical power at different voltages and currents. The wiring harness is designed with conductors that vary in thickness depending on the load they carry. High-current lines supplying pumps are made of thicker copper wires with low resistance, while signal lines connecting sensors to the control board use thinner wires optimized for data transmission. This design ensures that no energy is wasted through heating and that no signal integrity is lost due to interference. The routing of wires inside the harness follows strict principles: minimizing crosstalk, reducing exposure to vibration, and maintaining easy access for servicing. By organizing wires into a harness rather than leaving them loose, manufacturers not only reduce the risk of accidental disconnection but also ensure efficient assembly during production. Moreover, the harness incorporates connectors that allow for quick disassembly and replacement of modules without cutting or soldering wires, thus supporting modular maintenance. When we understand how power flows through the purifier, it becomes clear that the wiring harness is the backbone of this process, silently carrying the lifeblood of electricity across the entire system with precision and reliability.

One of the most critical roles of the Water Purifier Wiring Harness is safety. A water purifier is an electrical appliance constantly exposed to moisture, pressure fluctuations, and high-frequency usage. Without robust safety mechanisms built into the harness, the risk of electric shock, fire, or component damage would be unacceptably high. This is why harness design incorporates multiple layers of protection. First, insulation materials are chosen for their dielectric strength, flame resistance, and tolerance against heat. PVC, Teflon, or cross-linked polyethylene are common choices due to their ability to resist melting and degradation over time. Second, the harness is engineered with waterproof connectors that seal against water ingress, preventing electrical shorts even when exposed to droplets or humidity. Third, fuses and circuit breakers are integrated into the harness system to immediately cut power if an overload or short circuit occurs. These safeguards are not optional luxuries but essential design elements that protect both the user and the appliance. Additionally, proper harness routing ensures that wires do not rub against sharp edges inside the purifier casing, which could otherwise lead to insulation wear and eventual electrical failure. The importance of such preventive design cannot be overstated because even the smallest compromise could result in failure at the exact moment when clean drinking water is needed most. The wiring harness thus serves not only as a functional connector but as the guardian of safety, ensuring that the purifier operates in an environment where electricity and water coexist without risk.

Durability is another defining factor in the Water Purifier Wiring Harness, and it directly influences the life span of the appliance. A water purifier is expected to run reliably for years, often in kitchens, factories, or offices where environmental conditions vary significantly. Heat from motors, moisture from the water itself, dust from surrounding air, and vibration from constant pumping cycles all place stress on the harness. To survive these conditions, the harness uses conductors made from high-purity copper or copper alloys that resist corrosion and maintain conductivity over time. The insulation materials are designed to withstand continuous exposure to humidity without swelling or cracking. Protective sleeves or corrugated tubes are sometimes added to further shield wires from abrasion and mechanical stress. The choice of connectors also contributes to longevity; gold or tin-plated contacts resist oxidation, ensuring that electrical connections remain strong even after thousands of plug-and-unplug cycles during servicing. By extending the durability of the wiring harness, manufacturers indirectly extend the lifespan of the purifier itself, as most failures in electrical appliances can often be traced back to wiring issues. This makes the harness not just a passive component but an active contributor to product reliability and customer satisfaction.

Efficiency in water purification is not only about how effectively contaminants are removed but also about how smoothly and quietly the appliance operates. The Water Purifier Wiring Harness contributes directly to this by ensuring stable and uninterrupted current flow to all modules. For example, when a pump receives steady power, it runs at optimal speed without fluctuations, reducing noise and energy wastage. When UV lamps receive consistent voltage, they maintain sterilization efficiency without premature burnout. Similarly, when sensors transmit accurate signals without interference, the control system can make precise adjustments that optimize purification cycles and minimize water wastage. From the user’s perspective, this translates into a smoother experience—clean water delivered on demand, lower electricity bills, and a quieter environment. By preventing power losses and miscommunication between modules, the wiring harness contributes to energy conservation and sustainability. Thus, while users may never see this hidden component, the quality of our daily interaction with purified water is heavily influenced by its performance.

The Water Purifier Wiring Harness is more than just a power distributor; it also acts as the communication bridge between intelligent components inside the system. Pumps, solenoid valves, pressure sensors, flow meters, and microcontroller-based control boards are all linked through the harness. This integration allows for real-time feedback and adjustments. For example, when a pressure sensor detects low inlet water pressure, it sends a signal through the harness to the control board, which in turn may shut down the pump to prevent damage. Similarly, a TDS sensor transmits data about water quality to the control unit, which can then alert the user or initiate additional purification cycles. The harness must handle both power lines and low-voltage signal lines in the same assembly without interference, requiring careful design to isolate circuits and maintain signal integrity. In reverse osmosis systems, where precision is paramount, such integration ensures that purified water meets health and safety standards consistently. The harness thus becomes not only an electrical component but also a facilitator of intelligent decision-making within the purifier, enabling advanced features that enhance both safety and performance.

The creation of a Water Purifier Wiring Harness requires strict manufacturing precision. Every wire length, connector type, and protective sleeve must be cut and assembled with accuracy to avoid slack or tension that could compromise performance. Automated crimping machines ensure consistent connector quality, while continuity tests verify that each wire is properly linked from end to end. Beyond the harness itself, supporting mechanical components play a vital role. This is where companies like Ningbo Jinyao Machinery Co., Ltd. make a significant contribution. As an enterprise integrating industry and trade, specializing in aluminum alloy precision castings and high-pressure die-casting molds, Ningbo Jinyao provides structural components such as brackets, housings, and mounting frames that allow wiring harnesses to be securely integrated into water purifier designs. By adopting advanced vacuuming, pin extrusion, and high-pressure spot cooling processes, the company ensures that every casted part meets the demanding tolerances required for global OEM standards. With the capacity to produce over 10,000 tons of precision castings annually and export to markets such as Japan and Sweden, Ningbo Jinyao has become a reliable partner for manufacturers worldwide. Its role in supplying durable components that complement wiring harness assemblies demonstrates how electrical and mechanical integration work hand in hand to create water purifiers that meet the highest expectations of performance and safety.

中文简体

中文简体