What are the main functions and structures of a heater wiring harness?

The primary function of a heater wiring harness is to connect the various electrical components in a heating system, ensuring safe and stable current flow and ensuring efficient operation of the heating system. A properly designed wiring harness not only improves the safety of electric heaters but also extends their service life.

Power Distribution: The heater wiring harness transmits power to the heating elements, enabling them to generate heat. The wiring harness often also distributes power to other accessories, such as auxiliary heating elements like fans or water pumps, to improve heat exchange and temperature control.

Control and Regulation: The wiring harness connects components such as thermostats, temperature sensors, and control boards, monitoring and regulating the temperature of the heating elements and ensuring the heater operates within a safe temperature range.

Safety Protection: To prevent hazards such as electrical faults and overcurrent, the wiring harness typically includes safety components such as fuses, circuit breakers, and grounding wires. These safety features ensure the reliability and stability of the heating system over extended use.

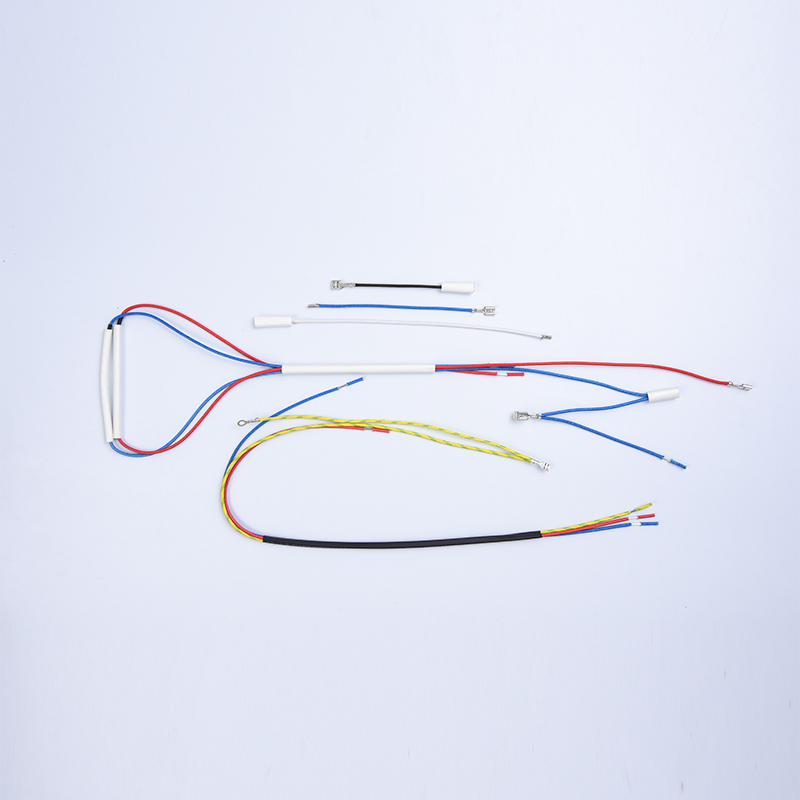

Cables/Wires: The core component of the wiring harness is the cable or wire responsible for transmitting current. The wires in a heater wiring harness must have sufficient current-carrying capacity and operate stably in high-temperature environments.

Connectors and connectors: Connectors and connectors connect cables to various electrical components, ensuring stable and reliable electrical connections. High-quality connectors and connectors can effectively reduce poor contact and current loss.

Insulation: Because electric heaters operate at high temperatures, the wires in the wiring harness must be made of high-temperature-resistant insulation to prevent current leakage or short circuits. Common insulation materials include silicone, PVC, and polytetrafluoroethylene (Teflon).

Protective tubing: In some applications, the entire wiring harness may also be covered with protective tubing to reduce physical damage to the cables from the external environment, especially in high-temperature or high-voltage environments.

What are the technical requirements for heater wiring harnesses?

Electric heaters typically operate at high power output and high temperatures, so the wiring harness must meet a series of technical requirements to ensure long-term stable and reliable operation.

High-temperature resistance: The heating elements of electric heaters typically generate high temperatures, and the wiring harness material must be able to withstand high-temperature environments to prevent aging, melting, or damage to the insulation due to prolonged heating. Common high-temperature-resistant materials include silicone and high-temperature-resistant PVC.

Current-Carrying Capacity: Electric heaters draw a lot of power, so wiring harnesses must have sufficient current-carrying capacity to prevent safety hazards such as overheating, damage, or fire caused by excessive current. Therefore, the wiring harness's conductors must have strong conductivity and low resistance.

Durability and Flexibility: Heater wiring harnesses may be exposed to vibration, bending, and friction during use. Therefore, materials with excellent flexibility and durability are required to prevent breakage and wear from long-term use.

Safety and Compliance: To ensure the safe use of electric heaters, wiring harnesses must meet strict electrical safety standards, such as UL, CE, and CCC certifications. These certifications guarantee high electrical safety and reduce the risk of electrical failure and fire.

Compatibility: The wiring harness must be compatible with the heater's other electrical components to ensure that connections do not cause current overloads or electrical interference. Appropriate design and material selection can help achieve this.

How does Cixi Tengyu Electric Appliance Co., Ltd. ensure that its heater wiring harnesses meet material requirements and industry standards?

Leveraging over 20 years of industry experience, Cixi Tengyu Electric Appliance Co., Ltd. consistently provides customers with heater wiring harnesses that meet international standards. The company's rigorous approach to material selection, custom design, quality control, and certification ensures its products meet stringent safety and performance requirements in the global market.

Conductive Materials: Cixi Tengyu Electric Appliance Co., Ltd. uses high-quality copper to ensure excellent electrical conductivity and low resistance in its wiring harnesses, ensuring efficient and stable current transmission to meet the demands of high-power heating systems.

Insulating Materials: The company uses high-temperature and aging-resistant insulating materials such as silicone and polytetrafluoroethylene to ensure the wiring harnesses are safe for use in high-temperature environments. These materials effectively prevent problems such as current leakage and overheating.

Protective Layer Materials: Cixi Tengyu Electric Appliance Co., Ltd.'s wiring harnesses can also be customized with additional protective layers, such as braided steel wire, to enhance wear and corrosion resistance, ensuring proper operation in harsh environments.

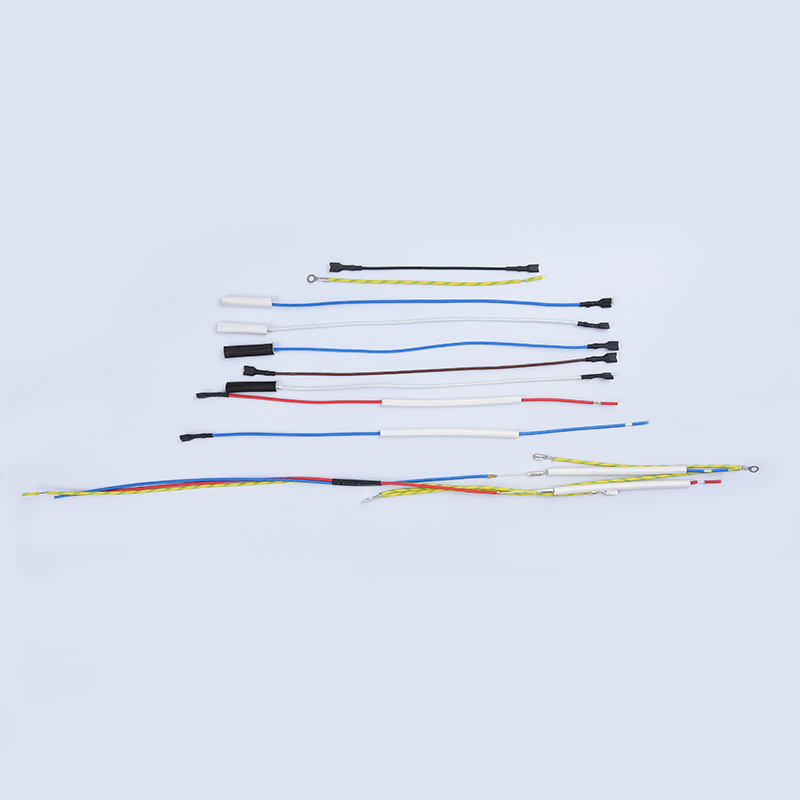

Cixi Tengyu Electric Appliance Co., Ltd. offers custom design services, capable of designing and manufacturing heater wiring harnesses tailored to specific applications (home appliances, automotive electronics, industrial equipment, etc.).

Home Appliance Applications: Wiring harnesses designed for home heaters require flexibility and high temperature resistance to handle the fluctuating temperatures and current loads found in home environments.

Automotive Electronics: In automotive heating systems, wiring harnesses must exhibit high vibration and heat resistance to withstand the challenging interior environments of vehicles.

Industrial Equipment: Cixi Tengyu Electric Appliance Co., Ltd.'s wiring harnesses are designed with the high voltage and high temperatures required in industrial environments in mind, ensuring long-term, stable operation.

Cixi Tengyu Electric Appliance Co., Ltd. employs a rigorous quality control system and has obtained multiple international certifications (such as UL, CE, and CCC) to ensure that every heater wiring harness meets global safety standards, guaranteeing electrical safety and reliability for users.

Quality Management System: Cixi Tengyu Electric Appliance Co., Ltd. rigorously controls every step of the production process to ensure product quality. Through precise quality control, our products are stable and reliable in various functional tests, meeting international safety standards.

Certification Standards: Cixi Tengyu Electric Appliance Co., Ltd.'s wiring harnesses comply with international certifications such as UL, CE, and CCC, ensuring global compliance and meeting the stringent electrical safety and environmental requirements of various markets.

中文简体

中文简体