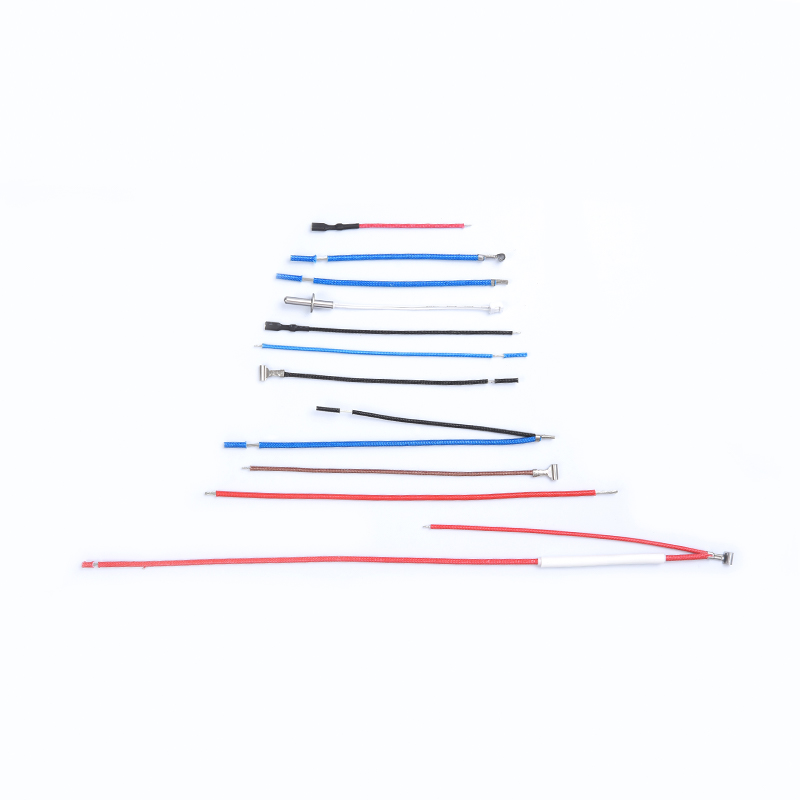

A garment steamer wiring harness is a crucial component of the steamer's internal electrical system, connecting electrical components such as the power supply, heating element, thermostat, steam generator, and indicator lights. It typically consists of wires, connectors, plugs, and insulation materials, ensuring smooth transmission of current and signals to the steamer's various components, ensuring proper function. The wiring harness not only transmits current but also plays a crucial role in temperature control, heating, and safety.

Cixi Tengyu Electric Appliance Co., Ltd., a leading supplier and manufacturer of garment steamer wiring harnesses in China, has over 20 years of industry experience. In the production of these harnesses, the company prioritizes material selection and optimized production processes. They utilize high-performance insulation materials that are resistant to high temperatures, wear, and aging. This ensures that the harness will not deteriorate due to aging, wear, or unstable current flow, even in high-temperature, long-term use. Tengyu Electric's design team also customizes wiring harnesses with varying specifications and functions to meet customer needs, ensuring a perfect match for each garment steamer, enhancing overall performance and safety. Tengyu Electric Appliance is committed to technological innovation and production process optimization. Through precise process control and efficient production processes, Tengyu is able to quickly respond to market demands, provide customized and fast delivery services, and meet the diverse needs of global customers.

How important is the role of the garment steamer wiring harness in the operation of a garment steamer?

The garment steamer wiring harness is a key component in ensuring the efficient and safe operation of the garment steamer. Its functions are primarily reflected in the following aspects:

Power Supply and Heating: The wiring harness ensures stable and efficient transmission of current to the heater and steam generator, enabling the garment steamer to heat up quickly and produce stable steam, effectively completing the ironing task. This efficient power supply not only helps the heater reach the set temperature but also ensures continuous steam output, meeting the temperature and steam volume requirements of different fabrics. With this stable power supply, the garment steamer can reach the desired operating state in a short time, ensuring that users can complete their ironing tasks quickly and efficiently, reducing waiting time.

Temperature Control and Adjustment: The wiring harness connects to the thermostat, ensuring that the garment steamer operates stably within the set temperature range. Through precise thermostat adjustments, the wiring harness helps the garment steamer monitor and adjust the heating element temperature in real time, preventing fabric damage from excessive temperatures or burnout from overload. Excessively low temperatures can prevent the steam from generating effectively, impacting the ironing experience. Therefore, stable transmission in the wiring harness is essential for the proper functioning of the thermostat, providing users with a safer and more precise ironing experience.

Safety Protection: High-quality wiring harnesses offer excellent insulation, effectively preventing electrical hazards such as leakage, short circuits, or fire. During use, the wiring harness is exposed to high temperatures for extended periods of time. Its excellent insulation ensures the safe passage of current without causing electrical accidents. Furthermore, the wiring harness's heat resistance prevents damage to wires and connectors, preventing electrical system failures caused by poor contact or aging. Ensuring the wiring harness has excellent insulation and safety ensures maximum user safety.

Steam Stability: The wiring harness ensures stable current flow and a smooth, continuous steam output. A high-quality wiring harness ensures accurate current delivery to the steam generator, ensuring stable steam generation to meet the ironing needs of different fabrics. For fabrics requiring higher temperatures and moisture levels (such as wool and silk), a stable steam supply can help remove wrinkles and improve the smoothness and gloss of fabrics. The wiring harness plays a crucial role in this process, directly impacting the stability of the steam system and the overall performance of the garment steamer.

Among these functions, the quality of the wiring harness directly affects the efficiency and safety of the garment steamer and is essential for ensuring efficient operation.

How to Choose the Right Wiring Harness for a Garment Steamer?

When choosing the right wiring harness for a garment steamer, it's important to consider the following key factors:

Compatibility: Different brands and models of garment steamers may have different internal electrical system designs. Therefore, when selecting a wiring harness, ensure it matches the specifications and power rating of the device. A poorly compatible wiring harness can lead to unstable wiring, affecting proper operation.

High-Temperature Resistance: Garment steamers generate high temperatures during operation, particularly in the heating element and steam generator. Wiring harnesses must be made of high-temperature-resistant materials (such as silicone insulated wire) to prevent aging or damage in high-temperature environments, ensuring long-term safe use.

Insulation and Safety: The wiring harness you choose should have high-quality insulation to prevent safety hazards such as current leakage or short circuits. It's best to choose wiring harnesses that comply with international safety standards (such as CE and UL certifications) to ensure electrical safety.

Flexibility and Durability: Wiring harnesses are subject to frequent movement and bending during use, making their flexibility and durability crucial. High-quality wiring harnesses should withstand repeated bending and stretching, ensuring long-term use without breakage or wear.

Supplier Reliability: Choose a reputable and experienced supplier who can provide high-quality wiring harnesses for your garment steamer and offer comprehensive quality testing, technical support, and after-sales service. A reliable supplier can provide high-quality products and ensure prompt resolution of any issues.

Common Faults and Solutions for Garment Steamer Wiring Harnesses

During extended use of a garment steamer, the wiring harness may experience some common faults. Understanding these faults and their solutions can help extend the lifespan of the device:

Aging or Damaged Wiring Harnesses: Wiring harnesses may age or break due to prolonged exposure to high temperatures, bending, and friction. Regularly inspect the wiring harness surface and insulation, and replace damaged components promptly.

Poor Contact: The connection between the wiring harness and internal components of the garment steamer may become loose or oxidized, leading to poor contact and impaired current flow. It is recommended to inspect the connectors and plugs, keep them clean, and ensure they are securely connected.

Electrical Faults: If a short circuit or leakage occurs in the wiring harness, it may cause the device to malfunction or create a safety hazard. Disconnect the power cord immediately and inspect the wiring harness insulation for integrity. If damaged, replace it immediately.

Prompt maintenance and repairs ensure the continued stable operation of the garment steamer wiring harness and avoid safety risks associated with malfunctions.

中文简体

中文简体