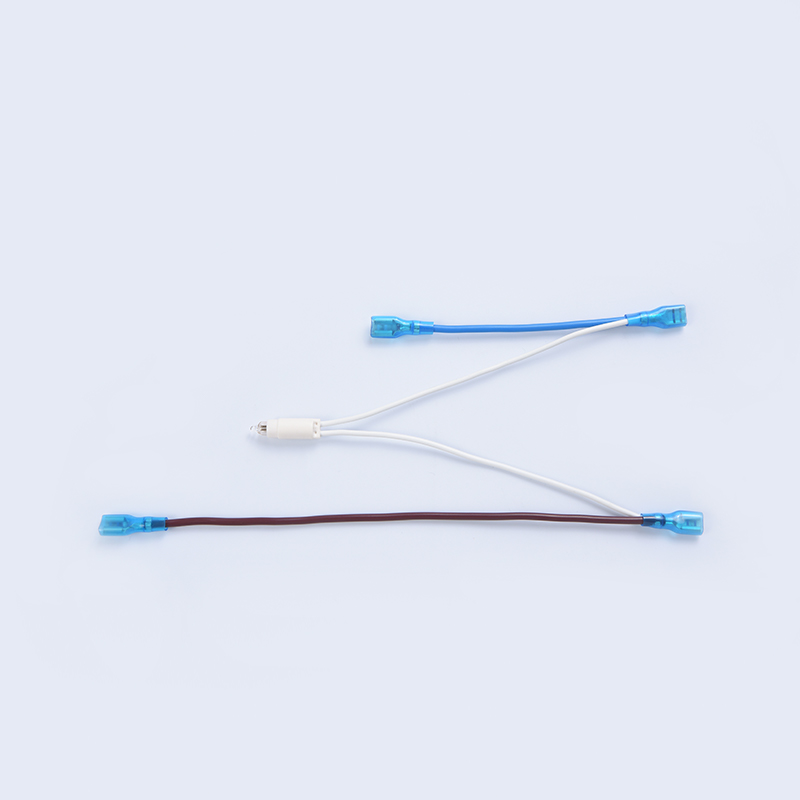

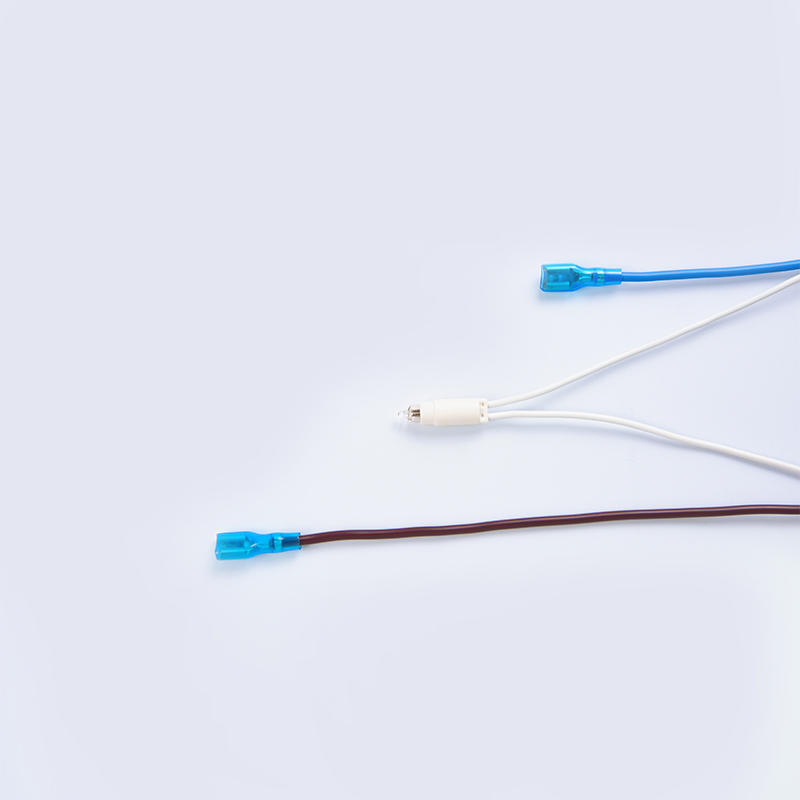

The wiring harness is the electrical connection system within an electric water heater, primarily responsible for connecting the power supply to components such as the heating element, thermostat, and sensors. It consists of wires, plugs, connectors, and insulation materials, ensuring stable current and signal transmission, thus ensuring the proper function of the electric water heater. Cixi Tengyu Electric Appliance Co., Ltd. adheres to strict quality control standards in the design and production of electric water heater wiring harnesses, ensuring that each harness meets the requirements for efficient and stable transmission. Wiring harnesses play a crucial role in the operation of electric water heaters, impacting heating efficiency, safety, and service life. With over 20 years of industry experience, Tengyu Electric is committed to providing customers with high-quality and reliable wiring harnesses to ensure efficient operation and long-term safety.

What are the functions of an electric water heater wiring harness?

A electric water heater wiring harness is more than just a channel for transmitting current; it also plays a key role in the following aspects:

Current Transmission: The electric water heater wiring harness is a crucial component of the electric water heater's internal electrical system, responsible for stably transmitting power to the heating element, ensuring that water heats quickly and efficiently. A high-quality electric water heater wiring harness effectively reduces resistance during current transmission, ensuring a stable flow of current and avoiding inefficient heating or uneven water temperature caused by unstable or uneven current transmission. The electric water heater wiring harness's conductor material, connectors, and insulation design all have a direct impact on current flow. An improper electric water heater wiring harness design can waste current, increase the water heater's energy consumption, and even prolong heating time. Therefore, using a high-quality electric water heater wiring harness can improve heating efficiency, shorten heating time, and provide a more uniform water temperature.

Temperature Control: The electric water heater wiring harness is tightly connected to the water heater's thermostat, ensuring the device automatically adjusts the operating state of the heating element according to the set temperature, maintaining the water temperature within the ideal range. A high-quality electric water heater wiring harness ensures accurate transmission of temperature control signals, preventing overheating or underheating due to poor signal transmission. Through precise temperature control, the electric water heater wiring harness effectively prevents overheating, protecting internal components from damage and enhancing user safety. A stable temperature control system also reduces the water heater's energy consumption, ensuring that the device heats water precisely when needed and avoiding energy waste.

Safety Protection: The electric water heater wiring harness connects to safety devices such as temperature sensors and circuit breakers, providing crucial protection against overcurrent. Through proper design, the wiring harness effectively transmits current and temperature signals. If the current overloads or the temperature rises abnormally, the safety system immediately disconnects the power supply, preventing safety hazards such as overheating and short circuits in the electric water heater. High-quality wiring harnesses are made of high-temperature and corrosion-resistant materials, capable of withstanding prolonged high-temperature operation and preventing electrical failures due to aging or damage. Ensuring the quality and connection of the wiring harness is a key element in electric water heater safety, preventing fires and other electrical accidents caused by wiring harness problems.

Signal Transmission: The wiring harness not only transmits current but also relays signals between the various components within the electric water heater. It accurately transmits signals from components such as the thermostat, sensors, and heating elements, ensuring coordinated operation of all systems. For example, a temperature sensor monitors changes in water temperature and transmits a signal to the thermostat, which then adjusts the power to the heating element to maintain the water temperature within the set range. Problems with signal transmission in the wiring harness can prevent the temperature control system from properly regulating the temperature, affecting heating performance and even causing the water temperature to overheat or underheat. A high-quality wiring harness ensures clear and accurate signal transmission, ensuring efficient operation and long-term stability of the entire electric water heater system.

How to Choose the Right Wiring Harness for an Electric Water Heater?

When selecting the right wiring harness for an electric water heater, consider the following key factors:

Compatibility with the electric water heater model:

Different brands and models of electric water heaters may have different internal electrical systems and structural designs. Therefore, wiring harness specifications, interface design, and wire lengths may also vary. When selecting a wiring harness, carefully consider the electrical requirements of the electric water heater, including power consumption, temperature control system, and heating element characteristics, to ensure the harness design is perfectly compatible with the device. The compatibility of the wiring harness with the electric water heater directly affects the device's operating efficiency and safety. Therefore, consult the device manual or consult a professional when selecting a wiring harness to avoid equipment failure or safety hazards caused by wiring mismatches.

Wire material: The wire material used in the wiring harness is crucial. Copper is a common material due to its excellent conductivity and stability, ensuring stable and rapid current transmission to the heating element. Copper reduces resistance to current flow, effectively improving the heating efficiency of the electric water heater and preventing uneven heating or prolonged heating time caused by unstable current. Copper wire also offers good corrosion resistance, making it suitable for the long-term, high-temperature operation of electric water heaters. High-quality wire material not only improves energy utilization but also reduces energy loss, ensuring efficient and energy-efficient operation of the electric water heater.

Insulation performance: The insulation material of the wiring harness must possess excellent resistance to high temperatures, corrosion, and aging to ensure long-term stable operation in high-temperature environments. The quality of the insulation layer directly determines the safety of the electric water heater. High-quality insulation material effectively prevents current leakage or short circuits, ensuring the normal operation of the device and the safety of users. Over time, low-quality insulation material may gradually deteriorate or crack, potentially leading to electrical failures and fire risks. Therefore, selecting a wiring harness with good insulation performance is essential to ensure the long-term safe operation of the electric water heater.

High-temperature resistance: The heating element of an electric water heater typically operates at high temperatures, so the wiring harness must exhibit excellent high-temperature resistance. If the insulation of the wiring harness cannot withstand high temperatures, it may degrade, melt, or crack, compromising the proper transmission of electricity and the safety of the device. In high-temperature environments, the wiring harness must effectively isolate the heat and maintain stable electrical performance to prevent electrical failures caused by overheating. Choosing highly heat-resistant materials, such as silicone and PVC, ensures that the wiring harness will not be damaged under prolonged high-temperature operation, ensuring the safe and efficient operation of the electric water heater.

Reliability and certification: Choosing wiring harnesses with international certifications, such as UL and CE, ensures that they meet stringent safety standards and quality requirements. This certification mark signifies that the wiring harness has undergone safety and performance testing by relevant organizations and complies with international electrical safety standards. This effectively reduces the risk of electrical failures or fire hazards caused by substandard materials or design flaws. Certified wiring harnesses offer enhanced reliability, especially in high-temperature, high-humidity, or complex electrical environments, ensuring the stability and safety of the electric water heater in various environments. Therefore, choosing a wiring harness with reliable certifications is the best way to ensure the safety and performance of your device.

What are common problems with electric water heater wiring harnesses and how can they be solved?

Common problems with electric water heater wiring harnesses include:

Poor wiring: If the connections in the wiring harness are loose or poorly connected, this can cause the heating element to not heat properly or to heat erratically. The solution is to regularly check the wiring harness for tightness to prevent poor contact.

Insulation damage: After prolonged use, the insulation layer of the wiring harness may degrade or degrade, leading to current leakage or short circuits. The solution is to regularly inspect the insulation layer and replace it promptly if any damage is found.

Overheating or damage: If the wiring harness is used in a high-temperature environment for a long time, it may overheat or degrade, causing unstable operation. The solution is to choose a wiring harness that is resistant to high temperatures and aging, and to avoid long-term exposure to high temperatures.

中文简体

中文简体