What is the wiring harness of the electric iron?

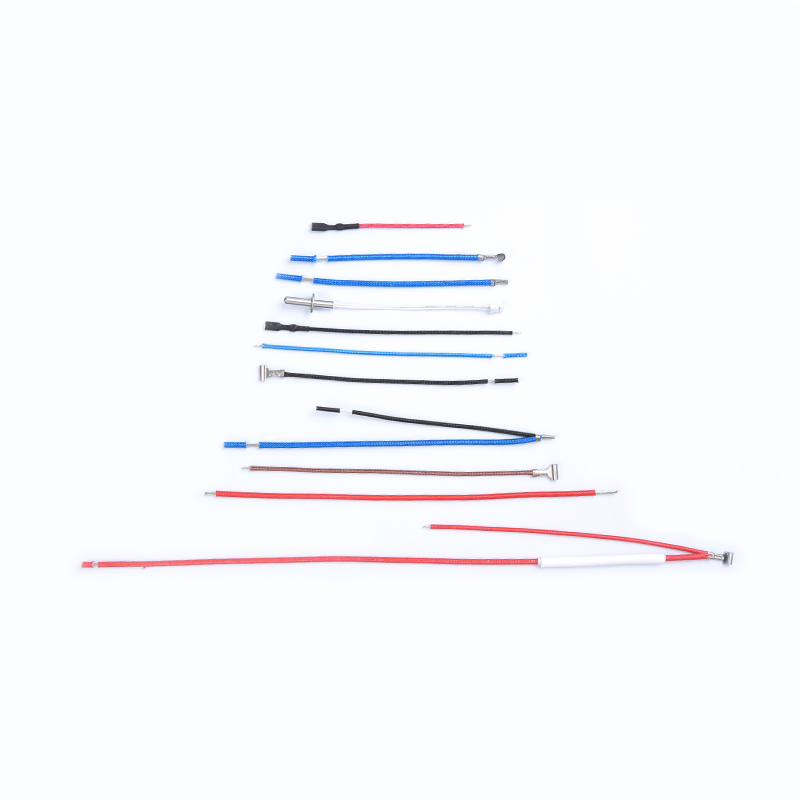

The electric iron wiring harness is an important part of the internal electrical system of the electric iron and plays a key role in connecting and transmitting current. It is mainly composed of multiple wires, connectors, plugs and insulation protection materials. These components are closely matched to ensure the stability and safety of the electrical system. The main function of the wiring harness is to connect the power supply to various electrical components inside the electric iron, such as heaters, thermostats, indicator lights, temperature control switches, etc., to ensure the smooth transmission of current, control signals and other electronic signals. Without wiring harness, the power supply cannot be effectively supplied to the heating elements, and the temperature control system cannot accurately adjust the heating power, which affects the normal use of the electric iron. Therefore, the wiring harness is not only a carrier of current transmission, but also plays a crucial role in the overall function and safety of the electric iron.

The quality of the wiring harness directly affects the working efficiency and safety of the electric iron. Especially in long-term high-temperature working environments, excellent wiring harness can ensure stable current transmission and avoid problems such as poor contact, overheating or circuit failure. In this regard, Cixi Tengyu Electric Appliance Co., Ltd., as Electric Iron Wiring Harness Suppliers, focuses on providing high-quality wiring harnesses for all types of appliances. Tengyu Company adopts advanced manufacturing technology to ensure the safety and efficiency of wiring harnesses and meet the needs of different types of electric irons on the market.

How important is the role of the electric iron wiring harness in the work of the electric iron?

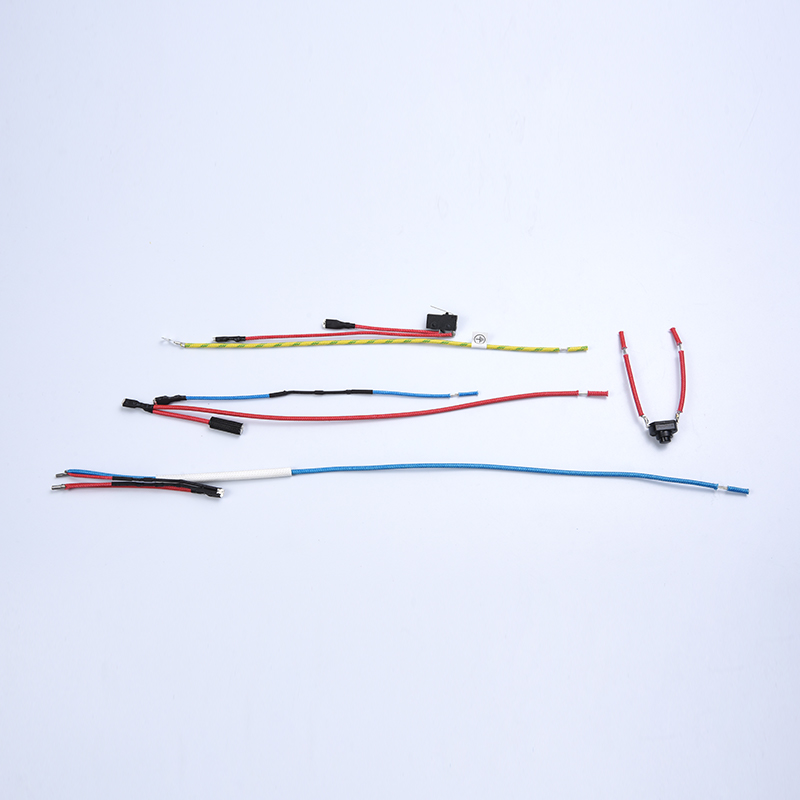

The electric iron wiring harness is like the "electrical nervous system", which determines whether the entire machine can work efficiently and safely:

Power supply and heating: Wiring harnesses play a crucial role in electric irons, which ensures that the supply current is transferred to the heater stably and efficiently, allowing the electric iron to heat up quickly and maintain a constant temperature. This process is crucial for the working efficiency of the electric iron, especially when high temperature steam or hot pressing is required, a stable current supply can ensure a more uniform and fast ironing effect.

Temperature control and protection: Through the wiring harness, the thermostat and indicator light can receive accurate signals, thereby accurately adjusting the heating power and avoiding damage to the electric iron due to overheating. The thermostat can maintain the optimal heating state at the set temperature to ensure that the iron does not overheat when used. During the signal transmission process, the wiring harness ensures the timeliness of system response and further enhances the safety and functionality of the electric iron.

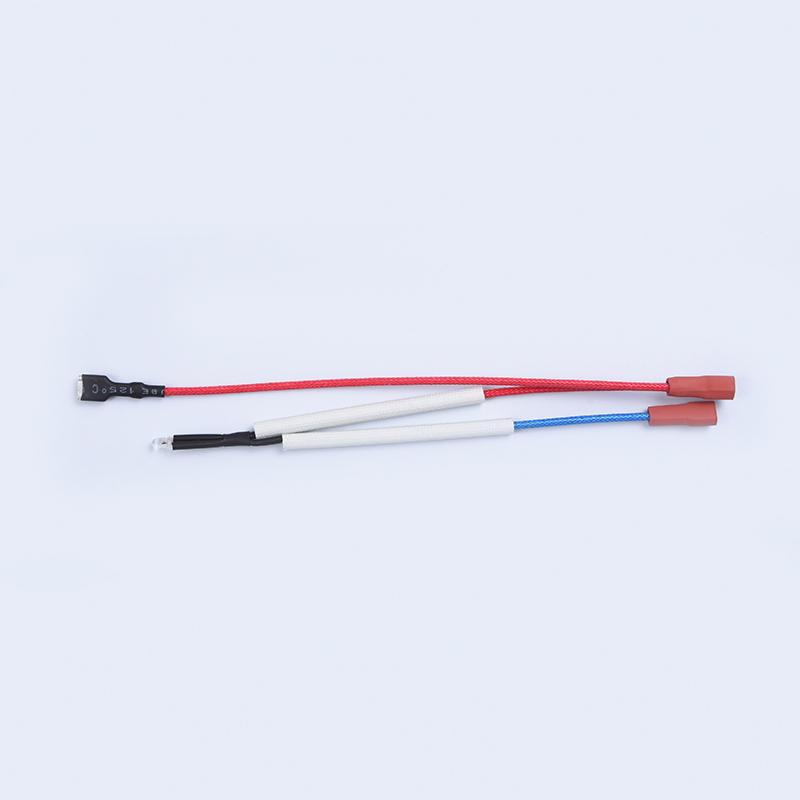

Safety protection: High-quality wiring harness has excellent insulation and heat resistance, can work stably at high temperatures for a long time and effectively prevent current leakage. It can prevent electrical problems such as leakage and short circuit, thereby reducing the risk of fire. Especially for equipment such as electric irons that are exposed to high temperatures for a long time, excellent wiring harness can significantly improve safety during use and ensure that users are not threatened by hidden dangers such as electric shock or fire.

Durability: The electric iron needs to frequently move and bend the wires during use. The flexibility and fatigue resistance of the wiring harness are directly related to the service life of the electric iron. High-quality wiring harnesses can withstand multiple bending and stretching, and will not be damaged or failed due to long-term use. Good durability means that even if used for a long time, the wiring harness can maintain stable power transmission, ensuring that the iron works normally, and not prone to failure or frequent replacement.

How to choose the right iron wiring harness?

When choosing a suitable electric iron wiring harness, in addition to considering the matching of the electric iron model, you also need to pay attention to the following factors:

Matchability: The wiring harness must match the model and design of the electric iron. The specifications, interface design and connection methods of the electric iron of different brands or power may vary. A mismatched wiring harness may not be able to connect to the internal components of the electric iron, and may even affect the normal operation of the iron, resulting in poor power supply, inaccurate temperature control or circuit failure. Therefore, when selecting a wiring harness, it is necessary to ensure that it is fully compatible with the specific model of the iron.

High temperature resistance: High temperature resistance materials should be used for high temperature resistance materials, such as silicone insulated wire or high temperature PVC materials, which can withstand the high temperature environment generated by the electric iron for a long time. The heating elements of the electric iron will work at high temperatures. If the temperature resistance of the wiring harness is insufficient, it may cause the wire to age and the insulation layer to be damaged, which will affect the normal operation of the iron and even cause safety hazards. High temperature resistance is the basis for ensuring the long-term stable operation of the wiring harness.

Insulation and safety: The wiring harness must comply with strict electrical safety standards, and the thickness and leakage resistance of the insulation layer should meet the specified requirements to prevent current leakage or short circuit. The ideal wiring harness should have international safety certifications such as CE and UL to ensure that during long-term use, there will be no electrical failures due to current overload, friction or high temperature, and ensure the safety of the user. At the same time, high-quality wiring harnesses should also have characteristics such as ultraviolet rays and water vapor resistance to adapt to various usage environments.

Flexibility and durability: The electric iron needs to bend and move frequently during use, so the flexibility and fatigue resistance of the wiring harness are crucial. Choosing a wiring harness with strong flexibility and wear resistance can effectively avoid breakage or damage after long-term use and extend its service life. A wiring harness with good durability can maintain its electrical performance even after repeated bending and stretching, ensuring that the iron always works stably and avoiding the hassle of frequent replacement of wiring harnesses.

Supplier Reliability: It is important to choose a reputable supplier, especially for electrically safe accessories. Suppliers should have a complete quality inspection system and after-sales guarantee to ensure that the wiring harnesses provided comply with national and international safety standards. A trusted supplier not only provides high-quality wiring harnesses, but also provides timely technical support and repair services when problems arise, so as to avoid safety hazards such as electrical failures or fires caused by the use of inferior wiring harnesses.

中文简体

中文简体