The design process begins with a comprehensive analysis of the electrical requirements of the HVAC system. This includes understanding voltage levels, current ratings, signal types, and specific routing constraints. Unlike generic wiring, a harness is engineered to consolidate multiple conductors into a unified system, which reduces installation time, prevents wiring errors, and minimizes the physical space required within the HVAC unit. Proper design must consider the thermal environment, potential sources of electromagnetic interference, and mechanical stresses from vibration or movement. Cixi Tengyu Electric Appliance Co., Ltd. leverages over two decades of research and development to optimize the layout of conductors, connectors, and protective elements, ensuring that electrical pathways maintain integrity even under continuous operation and high-load conditions. By adhering to these fundamental principles, Teng Yu Electrical Appliance creates harnesses that maintain stable electrical performance while preventing overheating, short circuits, and premature wear. The critical principle in harness design is modularity and adaptability. Modular harness segments allow for easier assembly, replacement, and upgrades without disturbing the entire system. This modular approach also facilitates standardized production, which enhances quality control and reduces the potential for errors during installation. The company’s scientific management system ensures that modular configurations are consistently replicated with precision, maintaining uniformity across all units while providing adaptability for diverse HVAC models.

Electrical pathway optimization is a core aspect of harness design. Each conductor must follow the most efficient route from the power source to the load while minimizing resistance, inductance, and potential crosstalk between circuits. Conductors are grouped based on their function—power supply lines, ground wires, signal lines, and sensor connections are routed separately to prevent interference and enhance signal clarity. Cixi Tengyu Electric Appliance Co., Ltd. employs internationally advanced production technology to determine optimal conductor routing using computer-aided design (CAD) simulations. These simulations allow engineers to visualize bending radii, potential points of mechanical stress, and spatial constraints, ensuring that harnesses can withstand operational demands without compromising electrical performance. By carefully planning conductor pathways, Teng Yu Electrical Appliance ensures that each harness can operate continuously without degradation, maintaining both energy efficiency and system reliability. Harnesses are often designed to accommodate dynamic movement within air conditioning systems. Components such as compressors, fans, and dampers create vibrations that could induce fatigue or conductor breakage over time. By implementing strategic routing, securing conductors with clips, and incorporating flexible sections, the harness design minimizes the mechanical strain on wires while maintaining connectivity under repeated motion.

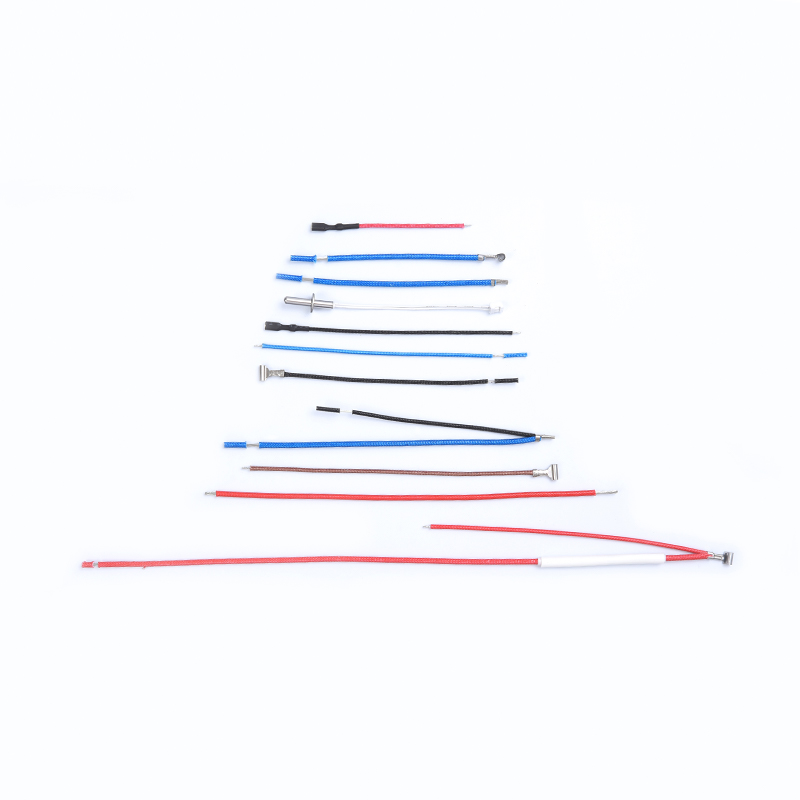

The placement of connectors and terminals is another crucial structural consideration. Connectors serve as junction points that enable electrical continuity and system modularity. Poorly designed connector placement can result in difficult installation, increased resistance, or mechanical stress on critical circuits. Cixi Tengyu Electric Appliance Co., Ltd. has developed proprietary methods for precise connector integration, ensuring that terminals align accurately, connectors fit securely, and contact resistance remains minimal. By conducting rigorous testing of connector placements under vibration, temperature variation, and repeated insertion/removal cycles, Teng Yu Electrical Appliance ensures the longevity and reliability of each harness. Terminal design also includes mechanical reinforcement to prevent loosening over time. Some harnesses integrate strain relief elements or reinforced crimping zones to maintain consistent electrical contact, even when exposed to mechanical stress. This approach is especially important in air conditioning units that experience fluctuating pressures, thermal expansion, or prolonged vibration, as it prevents intermittent connectivity that could compromise system performance or safety.

The wiring harness is exposed to a range of environmental factors, including heat, moisture, chemical exposure, and abrasion. Therefore, high-quality insulation is a critical component of structural design. Conductors are covered with durable polymer coatings that resist high temperatures and prevent electrical leakage. Harnesses often feature outer protective sheaths, braided coverings, or conduit routing to protect against mechanical damage and environmental degradation. Cixi Tengyu Electric Appliance Co., Ltd. has extensive experience in selecting and testing insulation materials that meet international safety standards. By controlling the quality of insulation and protective components through rigorous production processes, Teng Yu Electrical Appliance ensures that each harness maintains its integrity even under extreme operational conditions. The design also includes segregation of sensitive circuits. Signal wires carrying low-voltage or sensor data are often shielded and separated from high-current power conductors. This structural feature prevents electromagnetic interference, improves system accuracy, and ensures reliable operation of temperature sensors, fan speed controls, and other critical functions within the HVAC system.

Air conditioning systems have limited internal space, requiring careful management of harness layout. The structural configuration must accommodate tight bends, multiple components, and accessibility for maintenance. Engineers use CAD modeling and 3D spatial analysis to plan harness routing, ensuring that conductors do not interfere with moving components, airflow channels, or heat-generating elements. Cixi Tengyu Electric Appliance Co., Ltd. integrates these advanced design techniques to create harnesses that are both compact and functional. By efficiently utilizing space while maintaining safe distances between conductors, Teng Yu Electrical Appliance enhances installation efficiency and system reliability. Proper routing also facilitates heat dissipation. By avoiding contact with high-temperature surfaces and providing clearance from heat sources, the harness structure prevents insulation degradation and maintains consistent electrical performance.

中文简体

中文简体