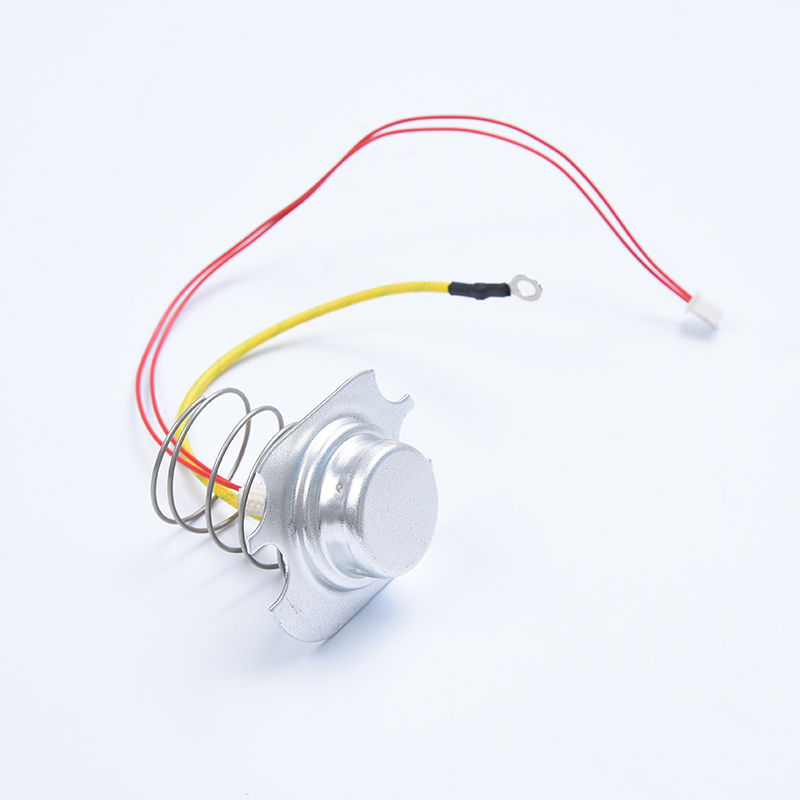

Basics of the Rice Cooker Center Cover Assembly

Q: What is the Rice Cooker Center Cover Assembly, and what is its function in a rice cooker?

A: The Rice Cooker Center Cover Assembly is a key functional component within the rice cooker, located between the inner pot and the outer shell. It is primarily responsible for steam guidance, sealing, and pressure regulation. Its rational design ensures even steam distribution, improving cooking efficiency while preventing steam backflow or water overflow, which directly impacts rice texture and cooking time. Cixi Tengyu Electric Appliance Co., Ltd. has over 20 years of experience, utilizing advanced production processes and a strict quality management system, and has established mature and stable technical capabilities in the design and manufacturing of center cover assemblies.

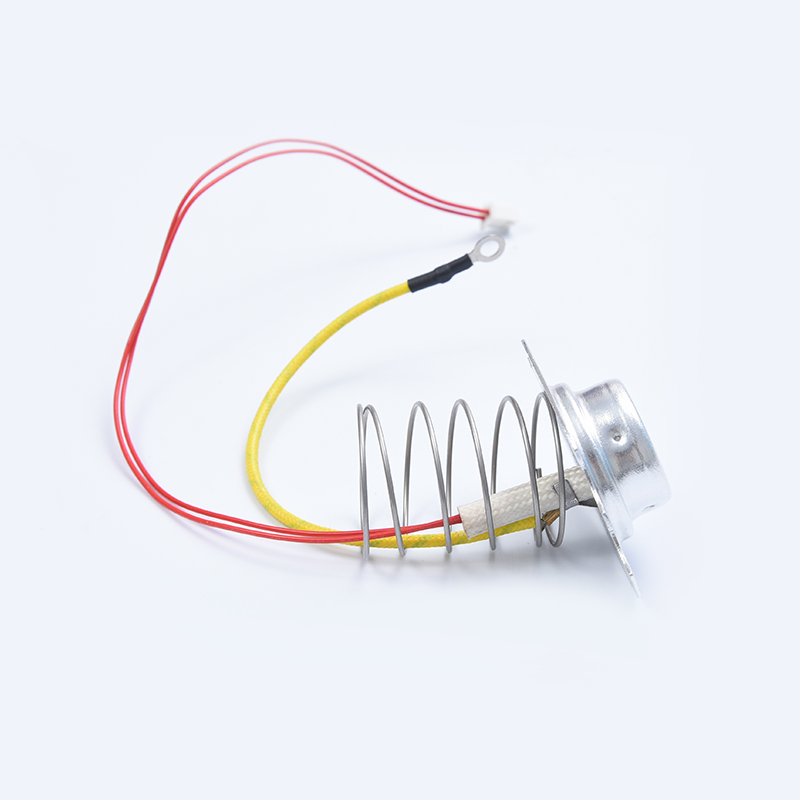

Q: What materials are center cover assemblies typically made of?

A: Center cover assemblies are typically made of a combination of high-heat-resistant engineering plastics, silicone sealing rings, and stainless steel. High-temperature-resistant plastics are used in the main structure to withstand the high temperatures of steam; silicone sealing rings ensure sealing performance and longevity; and stainless steel components enhance structural strength and provide corrosion resistance. Cixi Tengyu Electric Appliance Co., Ltd. rigorously selects materials to ensure that all components meet domestic and international high-temperature resistance and food safety standards, while also guaranteeing stable performance over long-term use.

Q: How does the design of the center cover assembly affect rice cooker performance?

A: The center cover design is directly related to steam release efficiency, heat uniformity, and safety. A well-designed air duct ensures even steam distribution across the inner pot surface, preventing localized overheating and burning. A well-sealed center cover prevents steam leakage, improving cooking efficiency and reducing energy consumption. Structural strength and wear resistance determine the component's long-term reliability. Cixi Tengyu Electric Appliance Co., Ltd.'s experienced R&D team continuously optimizes the center cover's fluid dynamics and thermodynamics through repeated simulations and testing, achieving efficient and stable cooking results.

Q: What are the key steps in the center cover assembly production process?

A: The key steps in the center cover assembly production process include injection molding, precision mold processing, seal assembly, and surface treatment. Injection molding requires ensuring the dimensional accuracy and high-temperature resistance of plastic parts; precision mold processing ensures a tight fit between component interfaces; sealing ring assembly requires a uniform fit to ensure a tight seal; and surface treatments, such as corrosion-resistant coatings, extend component life and facilitate cleaning. Cixi Tengyu Electric Appliance Co., Ltd. boasts internationally advanced production equipment and comprehensive process flows, with strict control at every stage to ensure components meet world-class standards.

Q: How do you ensure the long-term reliability and safety of the intermediate cover assembly?

A: Long-term reliability depends on material stability, precision manufacturing, and rigorous quality control. Intermediate covers operate in high-temperature and high-humidity environments, and material aging, seal failure, and structural wear are the primary risks. Cixi Tengyu Electric Appliance Co., Ltd. has established a rigorous production and quality inspection system, subjecting each batch of intermediate covers to multiple tests for high-temperature resistance, corrosion resistance, sealing, and pressure resistance, ensuring excellent, stable, and reliable product performance. Furthermore, the company's R&D team continuously refines its designs to optimize durability and safety, earning its products widespread recognition and acclaim in domestic and international markets.

How does the design of the rice cooker center cover assembly affect steam release efficiency?

Q: What is the core function of the rice cooker center cover assembly in a rice cooker?

A: The rice cooker center cover assembly, also known as the rice cooker center cover assembly, is the core component for steam management within the rice cooker. It not only seals the inner pot but also directs and regulates steam flow, directly impacting cooking efficiency and rice texture. A well-designed center cover effectively controls the speed and direction of steam release, ensuring uniform temperature within the inner pot and preventing local overheating or steam leakage. Cixi Tengyu Electric Appliance Co., Ltd. has accumulated over 20 years of experience in center cover design. With an advanced R&D team and precision production technology, we ensure that each component achieves industry-leading steam release efficiency.

Q: How does center cover design affect steam release efficiency?

A: The impact of center cover design on steam release efficiency is primarily reflected in the following aspects:

Steam flow channel design: The shape, length, and diameter of the flow channel within the center cover directly determine the steam release rate. A well-designed channel prevents steam from concentrating in a single direction and ensures even heat transfer. Sealing Structure: The precision of the seal and its components determines whether steam can escape smoothly or leak. Excessively loose or excessively tight seals can affect steam extraction efficiency, with the former wasting energy and the latter potentially causing overpressure.

Steam Outlet Position: The outlet's position and angle directly influence the steam diffusion path. A proper layout ensures rapid steam extraction while minimizing impact on the rice cooker's exterior and the user.

Material and Heat Resistance: The center cover is constructed of highly heat-resistant materials, capable of withstanding long-term exposure to high-temperature steam and preventing changes in steam extraction efficiency due to material deformation or aging.

Cixi Tengyu Electric Appliance Co., Ltd. has conducted multiple rounds of simulations and testing in these design stages to ensure that the center cover maintains stable steam extraction under high-temperature and high-pressure environments.

Q: Why is steam extraction efficiency so critical to cooking performance?

A: Steam extraction efficiency directly impacts the temperature distribution and cooking speed of the rice cooker's inner pot. Uneven or blocked steam extraction can cause localized overheating or underheating in the inner pot, resulting in a mushy rice bottom and uneven texture. Furthermore, improper steam extraction can waste energy and pose safety risks, such as pressure buildup or steam overflow. By optimizing the center cover design, Cixi Tengyu Electric Appliance Co., Ltd. is able to significantly improve heat utilization and shorten cooking time, while also ensuring product safety and user experience.

Q: How do we ensure the stability of the center cover's steam emission efficiency during the production and design process?

A: Ensuring stable steam emission efficiency requires multiple measures during R&D and production:

Precision mold manufacturing: Ensures the precise dimensions of each interface and flow channel in the center cover to prevent minor errors that could cause steam leakage or blockage.

Material selection and testing: Selects high-temperature and corrosion-resistant plastics and silicone seals, and subjects the materials to thermal cycling and pressure testing.

Fluid dynamics simulation: Computer simulation of the steam flow path optimizes the flow channel and outlet location.

Batch quality control: Each batch of center cover assemblies undergoes steam emission efficiency testing to ensure that all shipped products meet predetermined performance specifications.

Cixi Tengyu Electric Appliance Co., Ltd. utilizes internationally advanced production equipment and a strict quality management system. Every step demonstrates the company's high attention to product performance and customer experience.

How does a poor seal in the rice cooker center cover assembly affect rice cooker safety?

Q: What is the function of the rice cooker center cover assembly in a rice cooker?

A: The rice cooker center cover assembly is a key component within the rice cooker, primarily responsible for sealing the inner pot, directing steam flow, and regulating pressure. Its design not only impacts cooking efficiency and rice taste, but also directly impacts rice cooker safety. Cixi Tengyu Electric Appliance Co., Ltd. has accumulated over 20 years of experience in the design and manufacture of center cover assemblies. With comprehensive production technology and a strict quality management system, we ensure that every product meets international safety standards.

Q: What is a poor center cover seal?

A: A poor center cover seal typically refers to a loose contact between the center cover and the inner pot or steam guide mechanism, or a failed seal, leading to steam leakage, pressure fluctuations, or localized overheating. This condition can be caused by material degradation, manufacturing errors, improper installation, or design flaws. Cixi Tengyu Electric Appliance Co., Ltd. minimizes the incidence of seal defects through high-precision mold processing, material selection, and assembly process control.

Q: What impact does a poor seal on the middle lid have on rice cooker safety?

A: A poor seal can lead to a series of safety risks:

Steam leakage leading to burns: When the seal on the middle lid fails, high-temperature steam may spray out through the gap and directly contact the user's skin, posing a burn hazard.

Uneven pressure buildup leading to component damage: A poor seal can cause abnormal localized pressure within the cooker. Long-term use can cause deformation of the inner pot and damage to the steam valve, which in severe cases can compromise the overall structural safety.

Dry-cooking due to uncontrolled cooking temperature: Steam leakage lowers the temperature within the cooker, causing water to evaporate too quickly, potentially triggering the dry-cooking protection function and causing overheating of the inner pot and heating plate.

Increased energy consumption and reduced efficiency: Steam is not effectively utilized, resulting in prolonged heating time and wasted energy. This also increases the thermal load on components and shortens their lifespan. During the design process for the center cover, Cixi Tengyu Electric Appliance Co., Ltd. conducted fluid dynamics analysis, sealing ring material selection, and high-temperature resistance testing to ensure stable and reliable sealing performance, mitigating safety risks at the source.

Q: How can the risk of center cover sealing failure be reduced through design and production processes?

A: Reducing sealing failures primarily relies on scientific design and strict production control:

Precision dimensional control: High-precision molds ensure a tight fit between the center cover and the inner pot, minimizing assembly errors.

Optimized sealing materials: Highly heat-resistant and corrosion-resistant silicone sealing rings are used to ensure long-term use without deformation or aging.

Surface treatment and processing: The contact surface of the center cover is smoothed to reduce micro-gaps and enhance sealing effectiveness.

Quality inspection and testing: Each batch of products undergoes pressure testing, steam leakage testing, and heat cycle testing to ensure that the sealing performance meets design standards.

Cixi Tengyu Electric Appliance Co., Ltd. utilizes internationally advanced production equipment and a strict quality management system to ensure the stable and safe operation of each center cover assembly.

Q: What are the long-term effects of a poor seal?

A: If sealing issues are not promptly addressed, they may result in:

A reduced overall rice cooker lifespan and frequent component replacement.

A reduced user experience, resulting in uneven rice texture or prolonged cooking time.

An increased risk of safety hazards, such as dry cooking and steam burns.

Therefore, the sealing performance of the center cover is not only a product performance indicator but also a crucial factor in ensuring the safety of the rice cooker. Cixi Tengyu Electric Appliance Co., Ltd., guided by the principle of "people-oriented, innovation-driven development," continuously optimizes the center cover seal design and manufacturing process to provide highly safe and reliable products to customers worldwide.

中文简体

中文简体