What are the differences in the design of the pressure cooker center cover assembly between different types of pressure cookers?

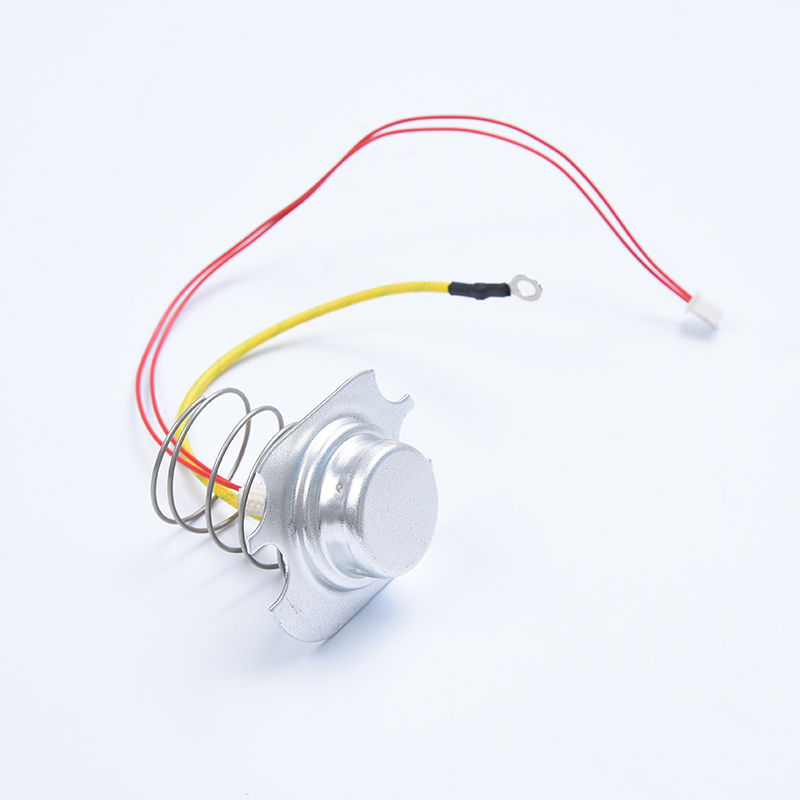

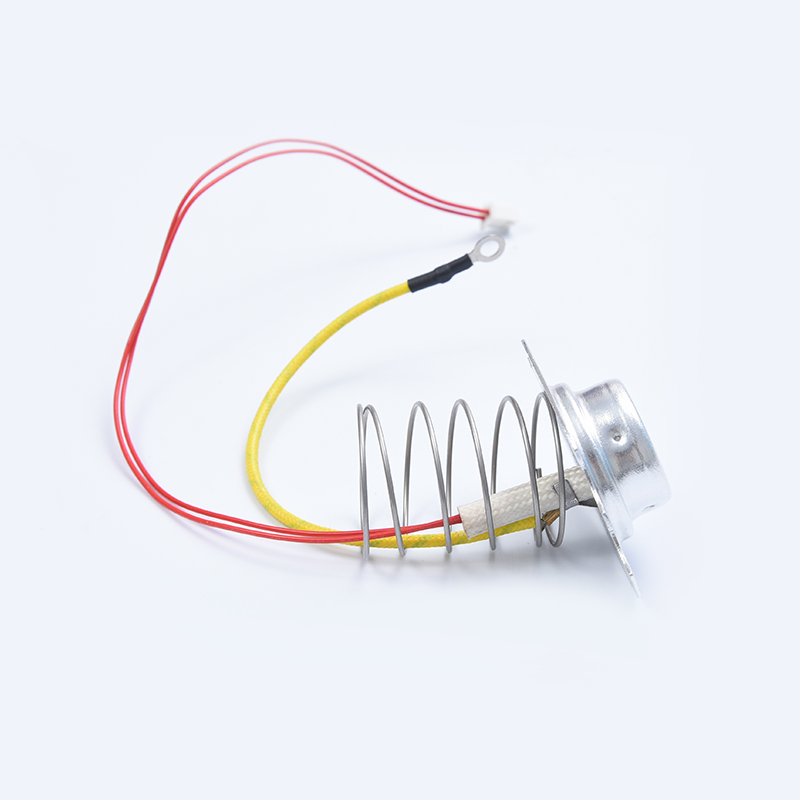

Cixi Tengyu Electric Appliance Co., Ltd., with over twenty years of development, has established itself as a leader in precision manufacturing of electric kitchen appliances. Among its core competencies is the design and production of Pressure Cooker Center Cover Assemblies, which are critical for ensuring safety, performance, and durability of modern pressure cookers. Different types of pressure cookers—ranging from traditional stovetop models to advanced electric multi-functional cookers—necessitate distinct design considerations for their center cover assemblies.

At Teng Yu Electrical, design engineers combine internationally advanced production technology with rigorous quality management to tailor assemblies for each cooker type. The key variations lie in sealing mechanisms, pressure regulation components, material selection, and user interface integration.

Stovetop Pressure Cookers

Stovetop models require center cover assemblies that can withstand direct heat and higher internal pressures, typically ranging from 80 kPa to 120 kPa. The sealing ring is usually made of high-temperature-resistant silicone or rubber, with a simple but robust pressure valve to release excess steam. The locking mechanism is predominantly mechanical, designed for secure engagement to prevent accidental opening during operation.

Electric Pressure Cookers

Electric models, including multi-functional cookers, integrate the center cover assembly with electronic sensors and automatic pressure control. Here, the assembly often incorporates a micro-switch or sensor to communicate lid status to the control panel. The design emphasizes airtight sealing to support consistent electronic pressure regulation, often at slightly lower pressure ranges (70 kPa–110 kPa) to balance safety with multi-functionality. Materials are selected not only for heat resistance but also for electrical insulation and durability under repeated thermal cycles.

Multi-Functional Pressure Cookers with Smart Features

Advanced smart cookers require center cover assemblies capable of integrating with digital pressure sensors, float valves, and automated locking systems. These assemblies feature precision-engineered components that maintain seal integrity while accommodating dynamic pressure adjustments during cooking cycles. Teng Yu Electrical leverages its R&D team's expertise to optimize the balance between mechanical reliability and sensor accuracy, ensuring consistent performance in both high-pressure and low-pressure cooking modes.

The following table summarizes key differences in design parameters among these types:

|

Parameter

|

Stovetop Pressure Cooker

|

Electric Pressure Cooker

|

Smart Multi-Functional Cooker

|

|

Max Operating Pressure

|

120 kPa

|

110 kPa

|

100 kPa

|

|

Sealing Material

|

High-temp silicone/rubber

|

Silicone with electrical insulation

|

Advanced silicone composite

|

|

Pressure Valve Type

|

Mechanical spring valve

|

Mechanical + sensor-assisted

|

Integrated electronic float and valve

|

|

Locking Mechanism

|

Manual mechanical

|

Manual + sensor detection

|

Automated electronic lock

|

|

Lid Sensor Integration

|

None

|

Lid detection switch

|

Full digital sensor array

|

|

Temperature Resistance

|

High

|

Moderate

|

Moderate-high with electronic compatibility

|

|

Maintenance & Replacement

|

User-friendly, simple

|

Requires careful disassembly

|

Requires professional servicing or guided replacement

|

What are the commonly used materials for pressure cooker center cover assembly and what are their respective advantages and disadvantages?

Pressure Cooker Center Cover Assemblies typically consist of several key components, including the main lid plate, sealing ring, pressure valve, locking mechanism, and sometimes integrated sensors for electronic models. Different materials are selected for each component depending on their mechanical, thermal, and chemical performance requirements.

Stainless Steel

Stainless steel is the most commonly used material for the main body of the center cover assembly. It offers high strength, excellent corrosion resistance, and the ability to withstand repeated thermal cycles without deformation. Stainless steel ensures structural integrity under high pressure conditions and is compatible with both stovetop and electric pressure cookers. However, stainless steel is relatively heavy, and machining complex components can be costly.

Aluminum Alloy

Aluminum alloy is sometimes used for lightweight or budget models. It has excellent thermal conductivity, allowing even heat distribution around the lid. The disadvantage is that aluminum is softer than stainless steel and more prone to scratches, dents, and potential corrosion if not anodized. Aluminum alloys may also require additional sealing support to ensure airtight performance under high pressure.

Silicone and Rubber (Sealing Rings)

The sealing ring is critical for maintaining pressure integrity. High-temperature silicone is widely used due to its excellent elasticity, heat resistance (typically up to 230°C), and chemical stability. Rubber is another option, offering flexibility and tight sealing, but it may degrade faster over time under repeated heating cycles. Teng Yu Electrical prioritizes medical-grade or food-grade silicone to ensure safety and long-term durability.

Heat-Resistant Plastics

Some non-load-bearing components, such as handles or valve housings, utilize heat-resistant engineering plastics (e.g., polyphenylene sulfide, PPS, or polyether ether ketone, PEEK). These materials provide good thermal stability, electrical insulation, and ease of molding into complex shapes. The main drawback is that plastics have lower mechanical strength compared to metals and may be susceptible to wear if improperly designed.

Composite Materials

For advanced electric or smart pressure cookers, composite materials combining metal and polymer layers are sometimes used in the center cover assembly. These composites offer a balance of mechanical strength, thermal insulation, and weight reduction. The challenge is higher production complexity and cost, which requires precise quality control—a capability well established at Cixi Tengyu Electric Appliance Co., Ltd.

The following table summarizes the most commonly used materials in Pressure Cooker Center Cover Assemblies, along with their main advantages and disadvantages:

|

Material

|

Common Use in Assembly

|

Advantages

|

Disadvantages

|

|

Stainless Steel

|

Main lid plate, structural components

|

High strength, corrosion resistant, durable under high temperature and pressure

|

Heavy, higher machining cost

|

|

Aluminum Alloy

|

Lid body, lightweight components

|

Excellent thermal conductivity, lightweight

|

Prone to scratches and corrosion, requires additional sealing

|

|

Silicone

|

Sealing rings

|

High elasticity, heat resistant, chemical stable, long lifespan

|

Higher cost than rubber, may degrade if low quality

|

|

Rubber

|

Sealing rings

|

Flexible, good sealing, low cost

|

Lower heat resistance, may wear faster over time

|

|

Heat-Resistant Plastics (PPS, PEEK)

|

Handles, valve housing

|

Thermal stability, electrical insulation, moldable

|

Lower mechanical strength, potential wear

|

|

Composite Materials

|

Advanced lid components

|

Combines strength, insulation, and weight reduction

|

Complex production, higher cost

|

中文简体

中文简体